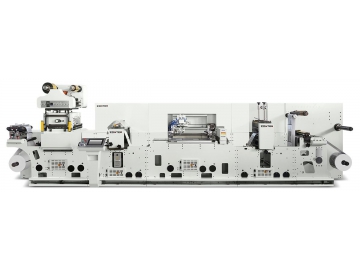

Semi-Automatic Flat Die Cutting Machine

The WB1300/1500 semi-automatic flat die cutting machine is a specialized die cutting machine used in colorful boxes and cartons. It has a number of advantages over similar die cutters on the market today. Gripping bars with a high intensity are applicable for different types of cardboard, paperboard and corrugated paper. A front, back and side registration mechanism ensures the precision of the die cutting. Other parts, like an intermittent mechanism with a high precision clutch and a pneumatic locking system are used. The flat die cutting machine features a programmable controller and an easy man to machine interface. The screen automatically shows the working speed, paper amount being processed and the total running time. It is easy to eliminate any possible trouble with a troubleshooting display. The main control motor uses a transducer.

The semi-automatic flat die cutting machine features a number of sensors and other safety equipment, ensuring the safety of both the operator and surrounding environment. The front and back pressure can be adjusted separately, and the machine can easily be stopped. The machine can also achieve die cutting without a clipper margin.

Main Drive

The main drive uses high quality steel alloy that is processed in a special manner to ensure the high precision, long service life and low abrasion.

Pneumatic Clutch

The pneumatic clutch is imported. It features a long endurance, and works quietly. The braking is stable and the clutching is fast with a strong driving force. The entire clutch conforms to European export standards.

Paper Delivery

The paper delivery component can automatically deliver the paper in the correct order. An online pneumatic sampling system can check the paper’s precision, and can automatically warn operators early if the speed drops or another malfunction occurs.

Die Cutting

The safety design of the die cutting floor, knife template and easily moved slewing device make installation and adjustment of the plate easier and faster. The bottom of the cutting plate uses a 3mm thick stainless steel, and the active base plate uses a 2mm thick aluminum plate, saving human resources, and is more efficient and convenient.

Gripper Bars

The gripper bars are made of a hard aluminum alloy, with a surface treatment of anode oxidation. It features a high intensity, low weight, and low inertia. The sheet transferring is carried out with a high precision and high speed.

| Model | ||

| Max. Paper size | 1300 x 950 mm | 1500 x 1080 mm |

| Min. Paper size | 550 x 500 mm | 550 x 500 mm |

| Max. Die cutting size | 1280 x 920 mm | 1495 x 1095 mm |

| Max. Die cutting pressure | 300N/CM ² | 300N/CM ² |

| Speed | 4500sheets/h | 4500 sheets/h |

| Max. Feeding pile height | 1400mm | 1400mm |

| Max. Delivery pile height | 1200mm | 1200mm |

| Power | 13.5 KW | 13.5KW |

| Weight | 14.5T | 16T |

| Size | 4000x2250x2250mm | 4200x2300x2250mm |