Vertical Clinker Cooler

Vertical clinker cooler is one of the main equipment in active lime clicination process. It is able to decrease secondary wear generated during cooling. The materials processed will be cooled during moving from the feed inlet to the discharge chute. Since the materials won’t cease to move forward during the cooling process, the cooling time will be reduced significantly and the air flowing to the related kiln will be heated quickly as well. The cooler ensures high performance and psychical characteristics of the finished product.

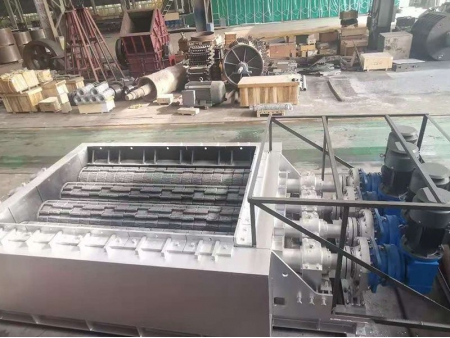

With high integrality, the cooler requires small installation space, which facilities maintenance. It is made up with barrel, supporting component and transmission component. The barrel consists of multiple high quality carbon steel made rolls which are welded together. Except the sections of first meter of both ends, the barrel is fitted with intersected angular lifting plates and screw blades in the interior and hold-material rings at the internal surface to prevent materials from returning backwards. The supporting component is supposed to prop up the total weight of the barrel. Moreover, it is required to ensure safe and stable operation of the barrel hovering on it.The supporting device entails riding wheels, pedestal and catch wheels, which are used to control the axial float of the rotating barrel. The transmission device consists of a motor, a reducer, a large gear and a small gear. Controlled by a electromagnetic speed motors motor, it features large transmission ration and large transmission torque.