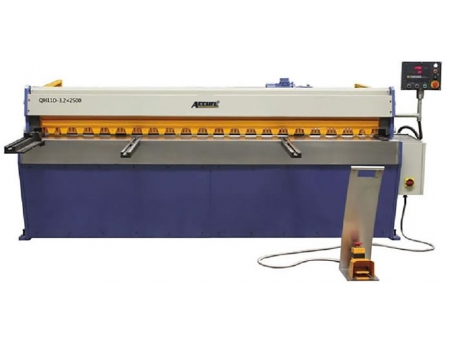

Power Guillotine Shear

The power guillotine shear is equipped with a unique clutch and an open gear drive. It works with advanced electrical devices to produce a very low noise level. This metal cutting tool features a one-piece welded steel construction, which provides the advantages of simple structure, easy operation and low energy consumption.

Maintenance Tips for Your Power Guillotine Shear

1. Add quantitative lubricant at a given point and in a timely manner before this sheet metal shearing machine is powered on. The oil must be clean and does not contain any sediment.

2. Keep the machine tool clean all the time. Those parts that have not been painted must be coated with anti-corrosive grease.

3. The lubricant inside the bearing of the motor must be replaced at regular intervals. Always check the electrical device to make it work normally, safely and reliably.

4. Add the lubricant to your machine tool and then clean this machine tool in 10 minutes before you get off work every day.

Cautions

1. Run this shearing machine at idle speed. Under normal circumstances, you can use this equipment to shear the sheet metal of different thickness and make a further understanding of the power guillotine shear.

2. Keep the equipment quiet in running. Once a noise occurs on the sheet metal shear, please stop running this equipment and then check it.

3. Make sure the sheet metal shear runs below 60℃ as the temperature of the fuel tank may rise.

4. Adjust the clearance between two blades before you start to cut a variety of sheet metal. This will ensure high durability of the cutter.

5. Don't increase the pressure in your power guillotine shear for cutting unspecified materials, or your equipment will be damaged.

6. Switch on the pressure gauge when the shearing machine works. The pressure for cutting a 12mm thick plate ought to be less than 20MPa.

Specifications of the Power Guillotine Shear

| Uses | Plate cutting machine |

| Motor Power | 43.5kW |

| Overall Dimension | 1580*850*1100 |

| Weight | 0.85T |

| Power Mode | Electrically powered |

| Size | 2m , 4m, 6m, 8m, 10m, or customized upon request |