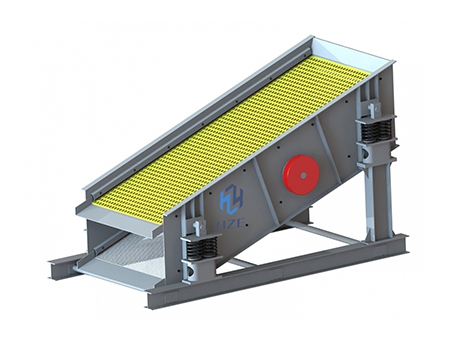

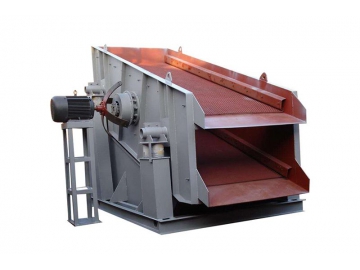

Vibrating Screen

Yonran vibrating screen is widely used for grading and sorting coals, quarry stone stocks, and ores into groups of different particle sizes in cement, building construction, chemical, and mining industrial processes. Excellent separation results and easy operation make this vibratory screener an ideal choice when it comes to quality vibrating screen separator.

Components

Featured vibrating screen consists of a sieving box, spring damper, motor base, motor (vibration exciter), etc. Cylindrical eccentric shaft is used to generate vibrations. Vibration amplitude adjustment is achieved via an eccentric weight. Long streams of multiple material flows mean materials can be screened and sorted into different size gradations. High separation efficiency, low noise level and adjustable vibration amplitude are three major benefits of our vibrating screen.

- Mesh screen, in double-deck and triple-deck configurations

- Motor-and-belt drive

Inner Workings

Get the vibratory screen started as the motor rotates an eccentric shaft at high speed. The eccentric weight installed inside the driven wheel produces continuous centrifugal force causing the framing to vibrate and travel in an elliptical circle. At this point, materials on the mesh screen are thrown out as undersize particles drop through the aperture, small-size particles form the bottom of the material bed, and over-size particles are thrown forward to exit the screener at the discharge end where they either fall into a hopper or land on a conveyor.

Features

1. Great vibration exciting force

2. Simple structure, easy repair

3. Tire shaft couplings are used for a flexible connection and steady running.

4. The screen framing is made of steel plates, with several mesh screens connected to each other via screw hooks for easy fixation and screen change.

5. Rivets are also used in place of screws to attach the mesh screen to the framing. Thus, there is no concern of screws shaking loose due to vibration.

6. To facilitate transportation, we cut mesh screens into sections of appropriate sizes. Installation of these screen sections is easily done with screw hooks. Hooked mesh screens are more flexible than one single large screen.

7. Low-amplitude, high frequency vibration, steep incline angle, high separation efficiency, large handling capacity, long service life

8. Low power consumption

| Model | Screen Size (MM) | No of Decks | Dimensions | Power(kW) | ||

| Length | Width | Height | ||||

| 280×420 | 2 | 2898 | 1594 | 1950 | 7.5 | |

| 250×400 | 3 | 2898 | 1594 | 2284 | 11 | |

| 400×600 | 4 | 2898 | 1594 | 2663 | 11 | |

| 500×750 | 2 | 3477 | 1600 | 2107 | 7.5 | |

| 600×900 | 3 | 3468 | 1599 | 2411 | 11 | |

| 750×1060 | 4 | 3480 | 1600 | 2730 | 11 | |

| 800×1060 | 2 | 4057 | 1900 | 2262 | 15 | |

| 870×1060 | 3 | 4057 | 1934 | 2573 | 15 | |

| 800×1300 | 4 | 4057 | 1934 | 2883 | 18.5 | |

| 900×1200 | 2 | 5689 | 2242 | 3054 | 15 | |

| 1000×1200 | 3 | 5689 | 2242 | 2743 | 18.5 | |

| 1200×1500 | 4 | 5689 | 2242 | 3054 | 30 | |

| 250×750 | 2 | 5689 | 2542 | 3394 | 22 | |

| 250×1000 | 3 | 5689 | 2542 | 3777 | 30 | |

| 250×1200 | 4 | 5700 | 2582 | 3996 | 37 | |

| 300×1300 | 2 | 5689 | 2842 | 3394 | 22 | |

| 250×750 | 3 | 5689 | 2842 | 3775 | 37 | |

| 250×1000 | 2 | 6258 | 2842 | 3654 | 37 | |