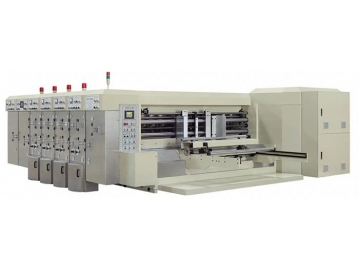

NC Corrugated Board Helical Cross Cutting Machine

NC Corrugated Board Helical Cross Cutting Machine

Cutting speed:

Effective width:

Cutting length:

Cutting precision: ±

The NC corrugated board helical cross cutting machine is one of the key components in a three, five, or seven ply corrugated fiberboard production line. Its computer control system is able to track the paperboard delivering speed so as to ensure synchronousness, and it can store over 200 groups of processing parameters to assure convenient operation when the machine is working for different tasks. A display screen is available to show the production information, and the production tasks can be expediently checked, modified, added, or canceled according to production schedule.

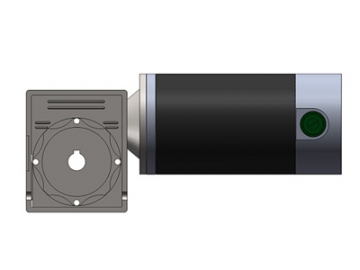

1. The cutter shaft is made of superior quality alloy steel and undergoes balancing treatment to keep good stability. It is directly driven by the electric motor, which simplifies drive mechanism design.

2. The reduced knife roll radius assists in reducing the rotary inertia of the roll as well as the main motor power.

3. Helical gear drive ensures low operation noise due to reduced cutting resistance.

4. The novel serrated cutting knife is allowed to be sharpened without stopping the machine, thus reducing the time required for cutting tool sharpening.

5. The cutting blades adopt oil pad lubrication method to extend the service life.

6. At the both ends of the knife roll, the gear backlash and tool setting is eliminated. The scissor-like cutting knife is convenient for adjustment. The knife roll is connected to the gear via a keyless bushing, which assures high precision connection and convenient assembly and adjustment.

7. The corrugated paperboard helical cross cutting machine comes with double layered wallboard.

8. Independent oil pumps and oil filters as well as two groups of copper tubes are available at each gear position for oil supply, lubrication, and cooling purposes.

9. The machine uses elastic rubber wheels for paper delivering. Offering uniform pressure force, the wheels ensure smooth and stable feeding, and also avoid the broken of paperboards.

10. The corrugated board helical cross cutting machine features low energy consumption. Its average electricity consumption is only 1/3 of the common types, which helps users to save operation cost effectively.

11. The precision gapless gears assure accurate cutting.

Related Names

Energy Saving Helical Cross Cutting Machine | Automatic Rotary Cross Cutter