CNC Machining Service

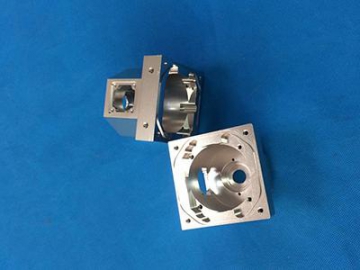

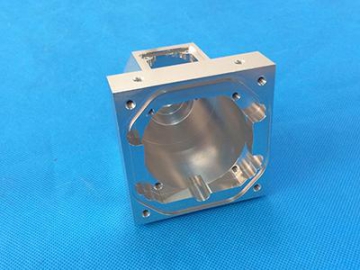

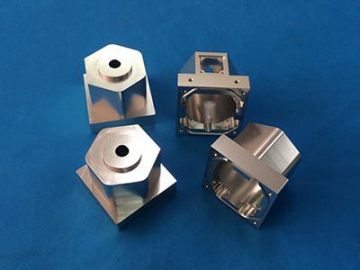

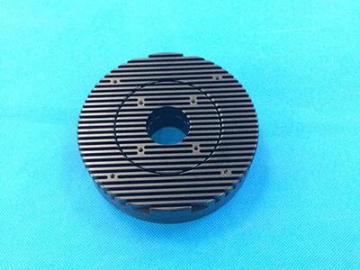

CNC machining has been widely used in various sectors where CNC milling and CNC turning allow cutting of any materials into the desired shape with great precision.

We have accumulated extensive experience in the machining industry after many years of processing services provided to our customers and thus we are here to provide you with the best CNC machining services. We are fully committed to every project to satisfy our customers' needs. Furthermore, we have a comprehensive quality testing scheme to ensure the quality of our products.

- High degree of automation with extraordinary productivity.

- The preparation cycle of the production process can be shortened because of the high adaptability to the processing object. When changing the machining object, the only thing needs to be done is reprogramming except for changing the tool and solving the blank clamping method, no complicated adjustment is required.

- High processing precision with stable quality. Because most of the operations are automatically performed by the machine, the human error is eliminated, the uniformity of the batch parts is improved. Moreover, the position detecting device is also adpoted in the precision-controlled machine tool, which further improves the precision of the numerical control machining.

- Establishing and implementing communication with computers is easy. It is also easy to make the connection between various machine tools because digital information control is adpoted, which eases the connection with the computer-aided design system to formation of a CAD/CAM integrated system.

| CNC Equipment | Processing Range | Processing Precision |

| CNC Machining Center (30) | 1800*600*350(mm) | 0.02mm. |

| CNC Machining Lathe (10) | Dia 400*1100(mm) | 0.02mm. |

- Aluminum

Characteristics Light weight | Resistant to corrosion

- Copper

Characteristics Heat conductor | Low electrical resistivity

- Stainless-steel

Characteristics Resistant to corrosion | Resistant to heat

- Alloy steel

Characteristics Hard | Resistant to corrosion | Resistant to heat

- Carbon steel

Characteristics Plasticity| Hardness

- Wood

Characteristics Resistance to stress | Beautiful appearance

- ABS

Characteristics Stable| Resistant to impact

- POM

Characteristics Stiff plastic | Elastic

- Nylon

Characteristics Stiff plastic | Light weight

- Acrylic

Characteristics Hard | transparent

- Polytetrafluoroethylene

Characteristics Smooth | soft

We use 3-axis, 4-axis, 5-axis CNC machine to process a wide range of materials.

Processing size: 0 to 3500mm

We are able to process the materials with tolerance controlled at ±0.05mm whereas the tolerance of the detail parts are controlled at ±0.02mm