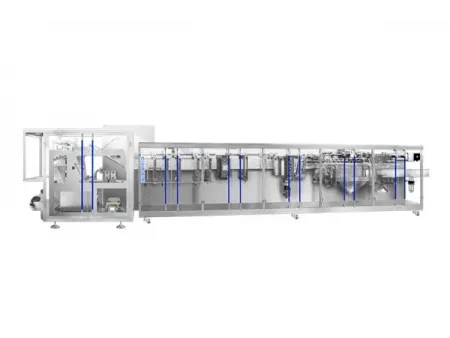

Stand-Up Pouch HFFS Packaging Machine, 2-Nozzle Filling

Horizontal form fill seal machine

These dual-nozzle rollstock stand-up pouch machines combine high output with efficient use of rollstock film and precise process control. The 2-nozzle filling (dual-lane) layout allows higher production speeds while keeping material waste low, and the servo-driven system helps maintain stable forming, filling, and sealing for consistent stand-up pouch quality.

- Film unwinding

- Film edge alignment

- Film forming

- Easy-tear notch forming

- Bottom sealing

- First vertical sealing

- Second vertical sealing

- Die cutting

- Cutting

- Pouch opening

- Air blowing

- Filling

- Heat sealing

- Cooling sealing

- Finished pouch conveying

- The pouch packaging output can reach up to 120 pouches per minute, which is suitable to handle large-volume orders that would be impossible to manage with manual or semi-automatic lines.

- A high level of automation connects pouch forming, dosing, filling, sealing, coding, and discharge into one continuous process, keeping production smooth and well-coordinated.

- The main frame and main components are made with high-strength materials and precision machining, so the pouch packaging machine can keep running steadily even during long production shifts and high-load operation.

| Performance features | Rollstock stand-up pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 70×110mm | 90×125mm | 90×125mm | 70×140mm |

| Max. pouch size | 90×225mm | 120×250mm | 120×250mm | 140×350mm | |

| Filling volume | 300ml | 500ml | 500ml | 800ml | |

| Packaging speed | 60-120 | 60-120 | 60-120 | 80-120包/min | |

| Rollstock film thickness | 60-180ųm | 60-180ųm | 60-180ųm | 60-180ųm | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 6900mm×970mm×1450mm | 7200mm×970mm×1460mm | 8500mm×1100mm×1460mm | 9500mm×1100mm×1460mm | |

| Operating conditions | Machine weight | 2100kg | 2500kg | 2500kg | 2500kg |

| Air consumption | 400L/min | 400L/min | 400L/min | 400L/min | |

| Main drive power | 8.8Kw | 9.8Kw | 9.8Kw | 15.8Kw |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

China Salt, a state-owned enterprise approved by the State-owned Assets Supervision and Administration Commission and the only designated multi-variety salt producer in Anhui Province, selected the 280SD rollstock stand-up pouch machine in 2022. Since the rollstock pouch packaging machine was put into operation, it has been running smoothly, and the customer has given very positive feedback on its performance in daily production.