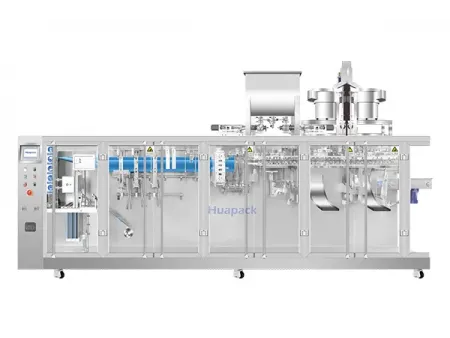

Zipper Pouch HFFS Packaging Machine, 2-Nozzle Filling

Horizontal form fill seal machine

The dual-nozzle rollstock zipper pouch machines are used to produce flat pouches with a reclosable zipper through a fully automatic process. From roll film, the zipper pouch packaging system carries out film pulling, zipper pressing, bottom sealing, filling, top sealing, and final cutting in sequence, delivering individual zipper pouches with three-side or four-side seals, ready for packing and downstream handling.

| Performance features | Rollstock flat pouch parameters | | | |

| Pouch parameters | Min. pouch size | 70x90mm | 70x120mm | 90x140mm |

| Max. pouch size | 120x225mm | 140x250mm | 160x300mm | |

| Filling volume | 150ml | 200ml | 400ml | |

| Packaging speed | ≤120 | ≤100 | ≤90 | |

| Rollstock film thickness | 70-150u | 70-150u | 70-150u | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 5200x970x1460 | 6500x970x1460 | 7200x970x1460 | |

| Machine weight | 2100kg | 2200kg | 2300kg | |

| Operating conditions | Operating temperature | ﹣10℃- 50℃ | ﹣10℃- 50℃ | ﹣10℃- 50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Air consumption | 300L/min | 300L/min | 300L/min | |

| Main drive power | 5.5kw | 5.5kw | 5.5kw |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

Founded in 2000 and headquartered in Haimen, Nantong, this high-tech pharmaceutical company focuses on high-value active ingredients and provides one-stop CDMO/CMO services for global drug manufacturers. After installing our pouch packaging equipment in 2023, their team has reported smooth operation and very positive feedback, highlighting the line’s reliability in daily production.