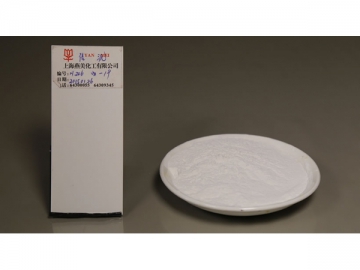

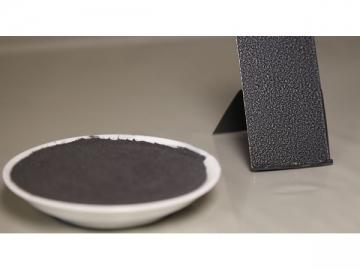

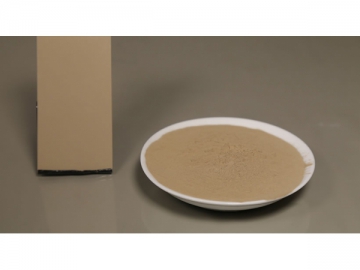

Smooth Finish Powder Coating for External Use

Main Features of Our Smooth Finish Powder Coating A. Excellent adhesion and a high hardness

B. High glossiness and great weathering resistance

C. Excellent durability and resistance to sunlight exposure

D. Excellent resistance to corrosion and pulverization

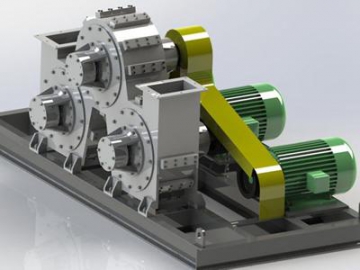

Applications Our smooth finish powder coating for external use is widely used in workpieces that need a corrosion and weathering resistance, such as outdoor furniture, bikes, automotive parts, air conditioners, fences, steel windows, and more.

Main Technical Indexes

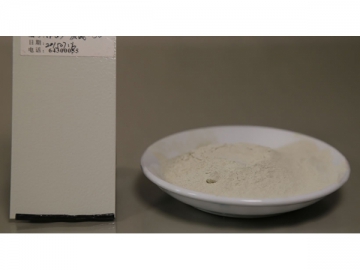

| Appearance (visual) | Porous without particle agglomerate, homogeneous color |

| Fineness (180 mesh sieve residue) | Less than 0.5% |

| Storage stability | 18 months |

| Curing conditions | 180℃-20min or 200℃-10min (can be set according to special condition) |

Coating Properties

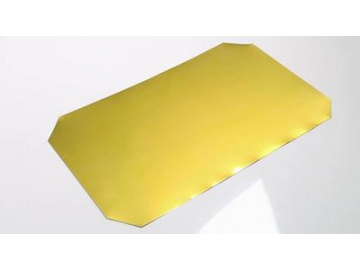

| Appearance of coating (visual) | Smooth, allow slight orange peel |

| Coating thickness | 60~80μm |

| Glossiness (60° light source) | High light >85% |

| Mid light 50%~84% | |

| Impact resistance (drop hammer) | 50kg (4.9Nm) pass |

| Cupping test | >7mm |

| Cross adhesion | 0 |

| Surface hardness | 2H |

| Salt spray test | 500hr. Pass |

| Humidity resistance | 500hr. Pass |

| UV test | Good, no pulverization phenomenon. |

| Water immersion test | 240hr. Pass |

| Acid resistance (5% HCL) | 240hr. Pass |

| Alkali resistance (5%NaOH) | 240hr. Pass |

Notes:

1. Powder coatings have a high standard for the working environment. The environment should have excellent ventilation and a temperature of less than 35°C.

2. The smooth finish powder coating should be stored in a cool, dry place, avoiding powder caking or solidification while spraying.

3. Our coating is 100% solid powder. Workers must take protective measures and wear protective clothing and avoid skin contact with the powder coating. If the skin does come into contact, was immediately with soap and water.

4. After the spraying process, the powder will be exposed to static electricity and create a coating layer on the workpiece in order to achieve the desired effect. The spraying device should be grounded, eliminating the static electricity from touching the device. By doing so, users ensure the entire coating and spraying process won’t be affected by static electricity.

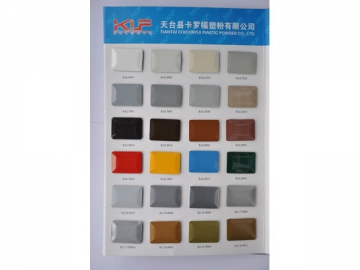

If you are interested in our product, please click the "" to choose the color you want.