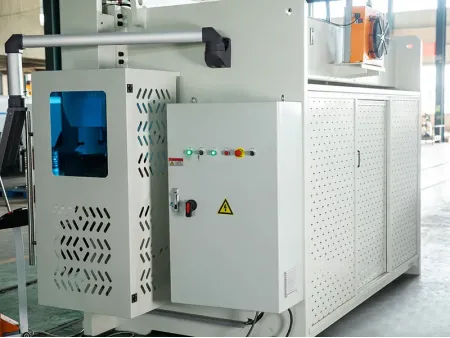

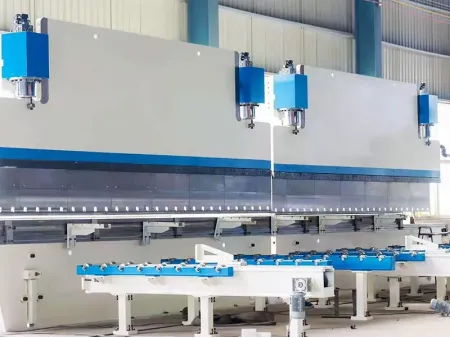

CNC Hybrid Press Brake

Sheet metal bending machine combining electric motor and hydraulic system for efficient metal processing

Sheet metal bending machine combining electric motor and hydraulic system for efficient metal processing

Key Specs

- Nominal force: 400KN-6000KN

- Distance between uprights: 1900mm-5000mm

- Throat depth: 250mm-400mm

- Features

- Specifications

- Examples

- Configurations

This compact CNC hybrid press brake, ideal for small workshops, features high-pressure bending capabilities powered by a motor-driven hydraulic pump. It is compatible with advanced CNC control systems such as Delem DA58T or Cybtouch 12PS, enhancing its suitability for a wide range of metal processing tasks. Common applications include bending for marine metal structures, elevator components, and medical equipment and supplies.

- Precision Control: Utilizes closed-loop synchronized control and a compensation mechanism to ensure high accuracy in bending operations.

- Advanced Programming: Offers 2D programming and 3D simulation capabilities to streamline and visualize bending processes.

- Enhanced Functionality: Includes a one-button die set release, touch screen interface, comprehensive compensation system, and offline programming capabilities. A multi-function foot switch and integrated laser protection device enhance safety and usability.

- Reliable Hydraulics: Equipped with a HOERBIGER hydraulic system, providing faster, more efficient, and stable performance.

| Model | Nominal force (KN) | Working table length (mm) | Distance between uprights (mm) | Throat depth (mm) | Ram stroke (mm) | Motor power (kW) |

| 400 | 2500 | 1900 | 250 | 100 | 5.5 | |

| 630 | 2500 | 1900 | 250 | 100 | 5.5 | |

| 800 | 2500 | 1900 | 250 | 120 | 7.5 | |

| 800 | 3200 | 2600 | 250 | 120 | 7.5 | |

| 1000 | 2500 | 1900 | 320 | 120 | 7.5 | |

| 1000 | 3200 | 2600 | 320 | 150 | 7.5 | |

| 1000 | 4000 | 3200 | 320 | 150 | 7.5 | |

| 1250 | 2500 | 1900 | 320 | 150 | 7.5 | |

| 1250 | 3200 | 2600 | 320 | 150 | 7.5 | |

| 1250 | 4000 | 3200 | 320 | 150 | 7.5 | |

| 1600 | 3200 | 2600 | 330 | 200 | 11 | |

| 1600 | 4000 | 3200 | 330 | 200 | 11 | |

| 2000 | 4000 | 3200 | 330 | 200 | 11 | |

| 2500 | 5000 | 4000 | 330 | 200 | 15 | |

| 3000 | 3200 | 2600 | 400 | 250 | 22 | |

| 3000 | 4000 | 3200 | 400 | 250 | 22 | |

| 4000 | 3200 | 2600 | 400 | 250 | 37 | |

| 6000 | 6000 | 5000 | 400 | 350 | 60 |

Standard Configurations

- Punch and die

- Grating ruler

- Auto crowning range from 0-3mm

- Siemens motor, Sunny pump

- Schneider electrical panel

- Controller Delem DA53T

- Backgauge x r axis

- Fine adjust finger

- KACON Foot Switch

Optional Configurations

Custom punch & die sets

Front gauge with linear guide

The hydraulic top die clamp features an automatic clamping and loosening action controlled electronically, ensuring a strong and reliable clamping force. This system facilitates quick and efficient tool changes.

Hydraulic bottom die clamp automatically manages the clamping and loosening actions via electrical control, streamlining the mold change process to increase efficiency and ease of operation.

Laser protection

Multi-axis backgauge

Control systems

- DA53T

- DA58T

- DA66T

- DA69T

- CT8

- CT12

- S630

- S660W