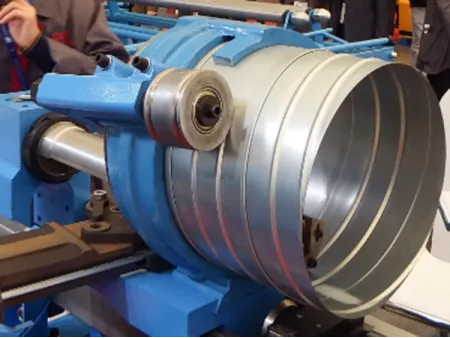

Spiral Duct Forming Machine

Request a Quote

DDGJ-1.2-1500-ZY

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

DDGJ-1.2-1500-ZY

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

- Structure: integrated type, suitable for transportation to the job site

- Spiral duct diameter range: 100mm to 1500mm

- Spiral duct thickness range: 0.5-1.2mm

- Feeding speed: 27 meters/minute, adjustable

Samples of Finished Spiral Ducts

Specifications

- Spiral duct diameter range100-1500mm

- Thickness range (Galvanized steel)0.5-1.2mm (strip width 137mm)

- Thickness range (Stainless steel)0.45-0.8mm (strip width 137mm)

- Uncoiler (Coil inner diameter)460-520mm

- Uncoiler (Max. coil outer diameter)1200mm

- Uncoiler (Max. coil weight)1000kg

- Lock-seam typeExternal lock-seam

- Feeding speed0-27 meters/minute (adjustable)

- Cutting methodRolling shear cutting or plasma cutting

- Power systemCutting and flipping use pneumatic power; feeding roller clamping uses hydraulic power

- Forming die materialSteel

- Machine weight2000kg

- Machine dimensions3.4×1.7×1.7m

- Discharge rack size2.1×1.0×1.0m

- Total power12kW

- Power supply380V/50Hz/3Ph

- Control methodTouch screen

Features

The spiral duct machine is specifically used for manufacturing spiral duct pipes of 0.5-1.2mm thickness. It uses a direct-connect integrated design, offering a compact structure that allows it to be transported to the construction site for efficient, on-site spiral duct fabrication.

With a 11kW main motor for strong power, the feeding speed of this air duct machine can reach 35 meters/minute, resulting in high efficiency.

This spiral duct machine uses die forming method to produce spiral duct pipes. Compared to traditional spread-wing type duct machines, this method results in a more secure lock-seam and more precise output diameter.