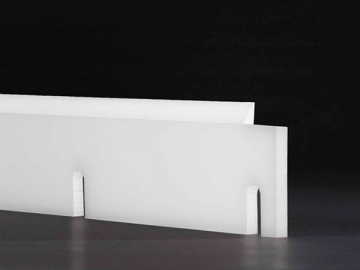

UHMWPE Scraper Blade

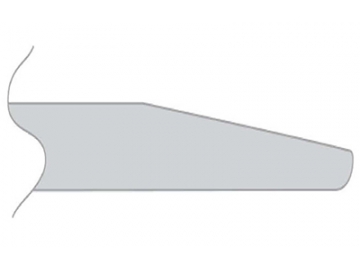

Xinxing UHMWPE scraper blades are finely crafted and are available in a variety of lengths for efficient drum filter applications. Our UHMWPE scraper blades are laser cut and sharpened to a 23-degree angle. The fine edge of this line of UHMWPE components increases blade life and reduces vibration.

To reduce the number of UHMWPE scraper blades required for a drum filter, Xinxing produces standard 6 inch blades as well as longer lengths including 12 inch, 18 inch, 24 inch, and 48 inch ones. Longer blades and fewer joints extended the blade lives for the filter. Additionally, our longer UHMWPE scraper blades are more easily installed and aligned, which leads to a reduction in filter downtime.

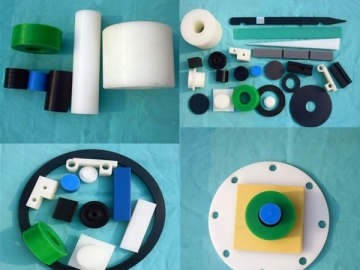

Features of the UHMWPE Machined Parts

1. Highly abrasion resistant

2. Reduce conveyor noise

3. Significantly reduced damage of material

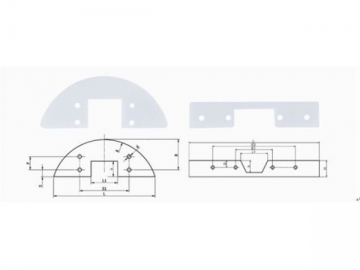

| Model | L | L1 | T | H | h | E1 | E2 | D | d |

| BF480×90 | 480 | 90 | 16 | 90 | 70 | 170 | 310 | 44 | 9 |

| BF380×90 | 380 | 90 | 15 | 90 | 70 | 155 | 255 | 44 | 9 |

| BF360×45 | 360 | 75 | 14 | 45 | 33 | 102 | 228 | 19 | 9 |

| BF305×55 | 305 | 70 | 14 | 55 | 37 | 95 | 195 | 22 | 9 |

| BF305×50 | 305 | 90 | 14 | 50 | 35 | 115 | 245 | 15 | 9 |

| BF305×45 | 305 | 75 | 14 | 45 | 33 | 102 | 228 | 19 | 9 |

| BF284×45 | 284 | 75 | 14 | 45 | 33 | 102 | 228 | 19 | 9 |

| BF184×45 | 184 | 75 | 14 | 45 | 33 | 102 | 19 | 9 | |

| BF145×45 | 145 | 75 | 14 | 45 | 33 | 102 | 19 | 9 | |

| BF255×49 | 255 | 70 | 14 | 49 | 35 | 105 | 190 | 16 | 9 |

| BF240×49 | 240 | 72 | 14 | 49 | 36 | 95 | 195 | 17 | 9 |

| BF208×49 | 208 | 70 | 14 | 49 | 36 | 90 | 150 | 17 | 9 |

| BF194×49 | 194 | 70 | 14 | 49 | 36 | 90 | 150 | 15 | 9 |

| BF185×50 | 185 | 90 | 14 | 50 | 35 | 115 | 15 | 9 |

| Industries | Applications | |

| Bulk material handling Conveyor equipment Parcel handling/distribution centers | Belt skirting Chute liners Conveying components: bearings, belt guides, chain guides, curves, guide rails, wear strips Dead plates Diverter bars Guide Rollers | Hitch plates Hopper liners Liners for gravity flow applications Roller covers Transfer plates Under belt wear strips |

| Properties | Unit | Method | |

| Density | g/cm3 | 527 / D 792 | 0.93-1 |

| Tensile strength at yield | MPa | 527 / D 638 | 17 |

| Tensile strength at break | MPa | 527 / D 638 | 40 |

| Elongation at break | % | 527 / D 638 | >50 |

| Modulus of elasticity in tension | MPa | 527 / D 638 | 650 |

| Modulus of elasticity in flexure | MPa | 178 / D 790 | 800 |

| Ball indentation hardness | MPa | 2039/1 | 35 |

| Impact Strength | kJ/m2 | 179 / D 256 | No br. |

| Creep rupture strength after 1000 hrs. with static load | MPa | ||

| Time yield limit for 1% elongation after 1000 hrs | MPa | ||

| Coefficient of friction against hardened and ground steel p=0.05 N/mm2, v = 0.6 m/s | - | 0.29 | |

| Wear conditions as above | um/km | ||

| Crystalline melting point | ℃ | DIN 53 736 | plus 135 |

| Glass transition temperature | ℃ | DIN 53 736 | |

| Heat distortion temperature Method A Method B | ℃ ℃ | R 75 R 75 | 42 ~70 |

| Max. service temperature short term long term | ℃ ℃ | plus 120 plus 90 | |

| Coefficient of thermal conductivity | W/(m K) | 0.41 | |

| Specific Heat | J/(g K) | 1.84 | |

| Coefficient of thermal expansion | 10-5/K | DIN 53 483 / D 696 | 20 |

| Dielectric constant at 105 Hz | DIN 53 483 | 3 | |

| Dielectric loss factor at 105 Hz | DIN 53 483 | ||

| Specific volume resistance | Ω cm | DIN 60093 | 1014 |

| Surface resistance | Ω | DIN 60093 | 1012 |

| Dielectric Strength1mm | kV/mm | ASTM 149 | 45 |

| Tracking Resistance | 53 480 | KA3c, KB>600,KC>600 | |

| Moisture absorption: Equilibrium in standard atmosphere (plus23℃/ 50% relative humidity) | % | 62 | 0.01 |

| Water absorption at saturation at plus23℃ | % | 62 | 0.01 |

| Resistance to hot water, washing soda | resistant | ||

| Flammability according to UL standard 94 | HB | ||

| Resistance to weathering | Natural: not resistant Black: resistant |