Glass Annealing Lehr

Request a Quote

Long oven used in the glass manufacturing process for uniform controlled cooling of glass ribbon from the tin bath

In flat glass production, the annealing lehr is used to cool the glass ribbon as it exits the tin bath. This process removes residual internal stress and eliminates optical distortions, ensuring stability in the glass structure. By carefully controlling the temperature curve throughout the lehr, the glass cools gradually without introducing new stresses, which guarantees mechanical strength, thermal stability, and optical uniformity.

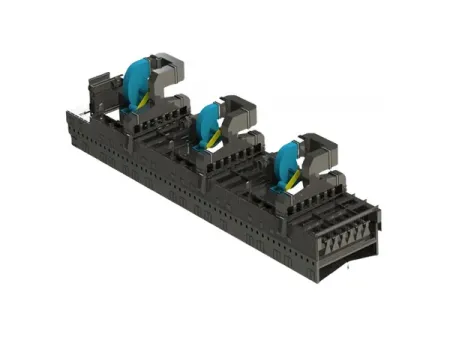

Our Glass Annealing Lehrs

Float Glass Annealing Lehr with Roller Conveyor

Specifications

- Power: 22-37kW

- Working pressure: 0.6MPa

- Transverse temperature tolerance: ≤30℃

- Output temperature fluctuation: ≤±2℃

- Production capacity: 1200t/d (max. raw sheet width 5.8m, min. sheet thickness 0.12mm)

- Glass pull rate: 30-1200t

- Glass thickness: 0.12-19mm

- Glass width: 4-5.8m

Rolled Glass Annealing Lehr with Roller Conveyor

Specifications

- Power: 15-18.5kW

- Working pressure: 0.6MPa

- Transverse temperature tolerance: ≤30℃

- Output temperature fluctuation: ≤±2℃

- Production capacity: 600t/d (max. raw sheet width 5.4m)

- Glass pull rate: 160-600t

- Glass thickness: 1.2-4mm

- Glass width: 2.4-5.4m

Advantages

- Sidewall temperature maintained within 30 °C above ambient conditions, enhancing safety and energy efficiency

- Multi-stage roller drive minimizes roller diameter differences during the cooling process, lowering the risk of scratches on the glass ribbon

- Gear grinding technology improves the accuracy of drive shafts and rollers, ensuring stable operation and consistent quality