Single Head CNC Stone Router

Photos of CNC stone router

- VCT-1018 SD

- VCT-1 325 SD

- VCT- 7090 SD

- VCT- 9015 SD

- 2520SD-2Z-2H

VICUT SD series CNC Routing system are perfectly used for stone marking and soft metal engraving, such as working on marble, granite, basalt, aluminum, and copper, etc. You can also use this router as an ordinary CNC single-head router to work on wood, acrylic and other nonmetal materials. With powerful spindles and special marble engraving bits, we can make wonderful routing, marking, and engraving jobs for you!

Features of CNC Stone Router

1. Base

The base frame of CNC stone router is made of heavy-duty tubular steel that is welded, precisely machined by gantry milling machine and stress relieved by vibration device. The gantry supports are enhanced so that the foundation remains steady over the operational life of the single-head CNC stone router.

2. Powerful Spindle with Water Cooling System

Quality 4.5kw water-cooled spindle of CNC stone router performs powerfully and stably in machining on marble and soft metal, also with solid wood, MDF, acrylic, and plastics, etc. Water cooling system can spray water during machining, makes your job safer and cleaner. Series of tools are available, including those of 3.175mm, 4mm, 6mm, 8mm and 12.7mm in diameter.

3. Gear Rack, Square Rails

We use precision gear racks for Y axis, carefully installed and calibrated by experienced workers with specialized instruments. This assures smooth motion and long term reliability of CNC stone router. 25MM square linear guide rails are from THK, mounted on all X, Y and Z axes. The guide rail is an ultra-heavy type with a deep grooved raceway with its diameter very close to that of steel balls running on it. The linear guide offers high rigidity, vibration and shock resistance. Besides, it is mounted on the upper surface of steel pipes for greater load bearing capacity and steadier movements.

4. Ball Screw

Quality TBI anti-backlash center driven ball screws come in 25mm or 40mm diameter and provide 0.01mm positional accuracy. The combination of ball screw and gear rack allows accurate, high-speed machining.

5. Stepper Motor

Industrial-grade maintenance-free stepper motor resists wear and allows powerful, fast machining.

6. Electric Cabinet

Housed within the mobile, double-door electrical enclosure are neatly wired electrical components which connect the CNC stone router to the power supply. This enclosure allows for easy access and servicing by users when needed. Each wire is tagged so that users can easily identify the cabinet when servicing is needed.

7. CNC Controller

PC-based controller provides user-friendly interface which allows operators to monitor and control the entire CNC stone router from a computer. Fast, high-precision motion control can be achieved thanks to the use of CNC display. Differential signal input and output facilitate signal control. Other desirable features include: power failure protection function, linear interpolation, circular interpolation, intelligent pre-fetch (prepared data beforehand for later use), reverse cutting, backlash compensation, breakpoint continuation and block skip, etc.

8. Water Tank

Stainless steel water tank holds water inside itself, specially designed for SD series router.

9. Oil Lubricator

Easier to lubricate the Guide units regularly. Just pull it gently and oil will go where it is needed.

10. Photoelectric Limit Switch

More sensitive and durable than traditional mechanical switch, maintenance-free for long term use.

11. Foot Pads

Foot pads make it easier to level the machine accurately

Technical Specifications

| Model | |||||

| Work Area | 1000×1800×180mm | 1300×2500×180mm | 700×900×180mm | 900×1500×180mm | |

| Spindle Power | 4.5KW Water Cooled | 3KW Water Cooled | |||

| Driver | Powerful Stepper Motor | ||||

| Tool Diameter | Ø3.175, Ø4, Ø6, Ø12.7mm | ||||

| Structure | Square Cast Tube | ||||

| Transmission | High precision gear rack for X,Y axes, TBI Ball Screw for Z axis | ||||

| XYZ Guide Rails | PMI Square Rails | ||||

| Machining Accuracy | <0.03/300mm | ||||

| Max. Engraving Speed | 8000mm/m | ||||

| Spindle Speed | 6000~24000rpm | ||||

| Data Transmission | Connect with PC directly (Original CNC display) | ||||

| File Format (programming language) | G code or HPGL | ||||

| Voltage | AC220V/50HZ or 380V/60Hz | ||||

| Net Weight | 700kg | Around 1100kg | Around 600kg | Around 700kg | |

| Packing Size | 2100×15 00 ×1680mm | 2100× 3000×1680mm | 1400×1200×1380mm | 2000×1400×1380mm | |

Optional Parts

1. Powerful Air Cooled Spindle

5.5KW air cooled spindle makes engraving jobs more stable and accurate.

2. Servo Motor

Panasonic AC Servo motor for smoother motion control and triple working speed, requiring no regular maintenance.

3. Handle Wheel

Anti-jamming and allowing long distance transmission of signal, with a 3m hand wheel cable; Accurate pulse output

Resolution: 100P/R; You can control machine movement by adjusting the hand wheel; that makes control operation easier and more convenient.

4. Tool Sensor

The tool sensor makes it easier to zero the Z axis, make single or multiple changes to the tool, and automatically calibrate the tool length. It helps save time and ensures error-free operation.

5. Feeding Rollers

They are high strength, wear-resistant rollers which help you load heavy stones easily.

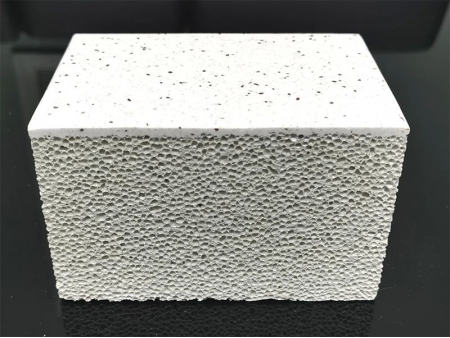

Samples workable with CNC stone router