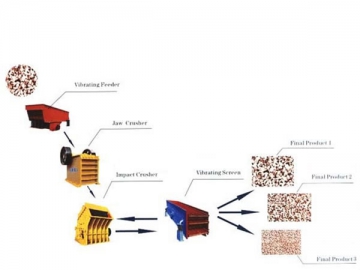

Stone Production Line

Our company provides a full set of stone production line and full-scale technical support service. The stone production line usually consists of vibration feeder, jaw crusher, impact crusher, vibration screen, belt conveyor and centralized control system. In addition, dust removal equipment is available if required. The dust removal device plays an important role in environment protection. Different types of machines will be assembled together to fulfill various technological requirements.

Generally, large stones are delivered into the jaw crusher through the vibration feeder for primary crushing at first. Then, the stones will be transported by the belt conveyor to the impact crusher to further reduce particle size. After secondary crushing, the belt conveyor will bring the particles to the vibration screen, which is able to sort out particles with different sizes. Particles with appropriate size will be directly transported to the finished product pile, while oversize particles will be returned to the impact crusher for further size reduction through the belt conveyor. In this way, a closed circuit working mode is created, which contributes to high production efficiency. Moreover, particle sizes of the finished product can be classified according to specific requirements from customers.

With our production line, a wide variety of materials can be used for aggregate production including granite, basalt, pebble, calcite, dolomite and limestone. The production line is primarily applied in areas such as construction of hydrop ower facilities, production of construction materials, construction of expressways as well as city construction.

Technical Parameters| No. | Maximum Feed Size (mm) | Capacity (t/h) | Model, Specification and Quantity of Devices | |||||

| Feeding Machine | Coarse Crushing Machine | Fine Grinding Machine | Screening Device | Belt Conveyor (m) | Installed Power (kw) | |||

| 1 | 340 | 30 | GZD8030(3kw) | PE400 × 600(30kw) | PF1008(45kw) | 2YK1235 (5.5kw) | 60-90(20kw) | 120 |

| 2 | 340 | 50 | GZD8530(4.4kw) | PE400 × 600(30kw) | PF1008(45kw) | 3YK1235(11kw) | 100-130(30kw) | 140 |

| 3 | 420 | 80 | GZD9636(10kw) | PE500 × 750(55kw) | PF1010(75kw) | |||