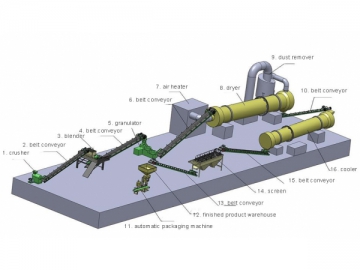

Ceramsite Sand Production Line

Ceramsite sand production line involves crushing, blending, grinding, pelleting, burning, coal powder preparation, cooling, screening and packing, etc.

Crushing

Generally, rocks from a quarry have a size ranging from 300 to 500mm and contain little water. After the primary crushing of jaw crusher and further crushing of hammer crusher, the size of raw materials is less than 8mm.

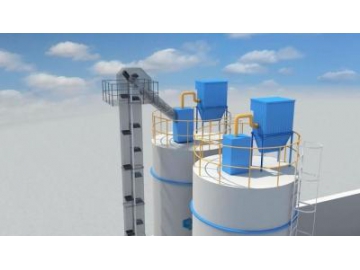

Blending

Different materials will be shipped into separate storage silos. Under each of these silos, a speed-regulating belt scale is equipped for measurement and blending later.

Drying

Either the flue gas from the rotary kiln or an exclusive air-heater can be used to dry the materials. The former method contributes to surplus heat utilization, which significantly reduce energy consumption.

Pelletizing

Raw material powder is stored in raw material warehouses. The production line is usually equipped with two or three warehouses. Each of them can discharge separately, or work together. Raw material powder is delivered into a small silo, under which a screw metering device or a speed-regulating belt scale is used to measure the raw material powder. After measurement, the raw powder enters the disc pelletizer. Later, pellets obtained are delivered into the screen. Qualified ones go to the rotary kiln, while oversize ones return back to the crusher for further size reduction. The number of disc pelletizer is decided by the capacity of the kiln in next procedure.

The pelletizing system features continuous process and high degree of automation. In addition, bag-house dust collector is provided to purify working environment. In fact, bag-house dust collectors are installed at every dust source in the production line to ensure clean production.

Burning

Ceramsite pellets are delivered into the slightly inclined rotary kiln for burning. These pellets move to the kiln head with the rotation of the kiln. Meanwhile, coal powder is blown into the kiln for buring. Pellets will be made into ceramsite sand with high strength through burning.

Production of Coal Powder

Ball mill or vertical mill is suitable for production of coal powder. Hot wind can be extracted from the kiln hood to dry the coal powder. Dynamic powder concentrator is able to adjust the size of powder as required, which contributes to sufficient combustion of coal powder.

Cooling

Generally, rotary cooler will be applied for cooling of ceramsite sand. The cooler features reliability and easy operation. The leaked wind from the cooler will enter the kiln entirely and then cooperates well with the multi-channel burner to reduce energy consumption significantly. Discharged from the cooler, the ceramsite sand has a low temperature, which enables operators to directly touch it with hands.

Screening

The cooled ceramsite sand can be directly transported to the multi-layer screen, which is able to sift the sand into different sizes according to demands of customers.

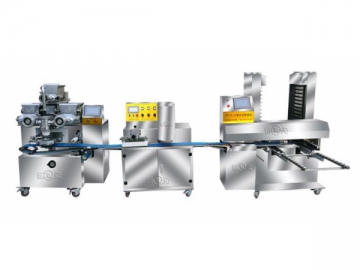

Packing

After screening, ceramsite sand with different sizes enters different silos, under which there is an electronic scale. Then certain amount of ceramsite sand is packed with bags which are sealed using sewing machine. The bags will be stacked up in the finished product warehouse for delivery.

Table One

| No | Name and Model | No | Name and Model |

| 1 | Edge Runner | 2 | Twin Roller |

| 3 | Box Feeder | 4 | Twin- Shaft Mixer |

| 5 | Roller Granulator | 6 | Cylindrical Rounder |

| 7 | Double-Barrel Rotary Kiln | 8 | Cooler |

| 9 | Dust Removal Device | 10 | Coal Mill |

| No | Name and Model | No | Name and Model |

| 1 | Slurry Mixer | 2 | Slime Pump |

| 3 | Twin- Shaft M ixer | 4 | Vibration Screen |

| 5 | Air Compressor | 6 | Disc Pelletizer |

| 7 | Double-Barrel Rotary Kiln | 8 | Cooler |

| 9 | Dust Removal Device | 10 | Coal Mill |

| No | Name and Model | No | Name and Model |

| 1 | Dryer | 2 | Ball Mill |

| 3 | Twin- Shaft Mixer | 4 | Disc Pelletizer |

| 5 | Double-Barrel Rotary Kiln | 6 | Cooler |

| 7 | DustR emoval Device | 8 | Coal Mill |

Major Economic Indicators

1. A nnual Prodution Capacity of 20,000 to 30,000 m 3

| No | Indicator Name | Unit | Value |

| 1 | Annual Capcaity | 10,000 m 3 | 2 ~ 3 |

| 2 | Annual Consumption of Raw Materials | ton | 16000 |

| 3 | Annual Fuel Consumption | ton | 2500 |

| 4 | Total Capacitance of Devices | KVA | 150 - 250 |

| 5 | Annual Water Consumption | ton | 15000 |

| 6 | Covering Area | acre | 15 |

| 7 | Working System | ||

| Production Shift | shift | 3 | |

| Working Days Per Year | day | 300 | |

| 8 | Direct Workers | person | 40 - 50 |

| 9 | Construction Investment(excluding fee for living facitities andland acquisition) | 10,000 yuan | 150 - 350 |

| 10 | Labor Productivity | m 3 / year . person | 500 - 600 |

| 11 | Investment for Per Unit of Product | yuan /m 3 | 100 - 180 |

| 12 | Product Cost E stimation | ||

| South China | yuan /m 3 | 80 - 100 | |

| North China | yuan /m 3 | 70 - 90 |

2. The total capital investment reaches to 5 to 9 million yuan for annaul capaticy of 50,000 m3.

3. The total capital investment reaches to 10 to 10 million yuan for annaul capaticy of 100,000 m3.