Windbreak Perforated Sheet Roll Forming Machine

Characteristics of the Windbreak Perforated Sheet Roll Forming Machine

1. The single-layered perforated sheet helps reduce dust by 65% to 85%. The double-layered windbreak perforated sheet helps reduce dust by at least 95%.

2. Those perforated sheets made by our rollformer machine are characterized by a beautiful exterior and low maintenance cost while providing a strong resistance to fire and theft.

3. This sheet metal machinery removes the need for surface coating, spraying and sealing technology. It also offers an effective solution for its operating limitations and dustproof performance, thus helping customers save much money.

4. The plastic-coated perforated sheets can absorb enough ultraviolet light to slow down the rate of oxidation, which contributes to superior ageing resistance and an extended service life. They are highly effective against sunlight as the ultraviolet radiation has a very low power of penetration.

5. These metal sheets are flame-retardant. They can fully meet the requirements for fire protection and safe production.

6. Thanks to its high mechanical strength, the windbreak perforated sheet has the capacity to resist hail and strong wind.

7. All these metal sheets have undergone electrostatic spraying process. When exposed to sunlight, organic contaminants can be removed from the surface of the metal sheet. Dust can be easily washed off the super-hydrophilic surface, thus helping to keep the surface clean and also save on maintenance costs.

Applications of the Windbreak Perforated Sheet Roll Forming Machine

1. Coal mines, coal preparation plants, cement plants, coking plants and power plants etc.

2. Ports, wharves, and a variety of manufacturing industries, such as cement, building materials, iron and steel etc.

3. Railways, highways, roads, construction sites, and so forth

Technical Parameters of the Windbreak Perforated Sheet Roll Forming Machine

| Materials | Low-carbon steel plates, color-coated steel plates, galvanized sheets, aluminum-zinc alloy-coated steel sheets, aluminum-magnesium alloy sheets, stainless steel sheets |

| Thickness of Base Plate | 0.4-1mm |

| Surface Treatment | Electrostatic powder coating Upon request, surfaces are available in custom colors. |

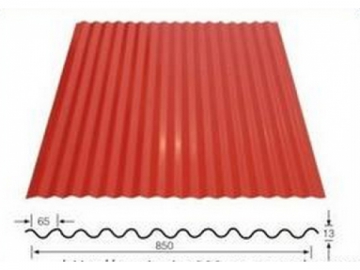

| Width of Single Peak | 270mm -450mm |

| Width of Triple Peak | 810-950mm, customized upon request |

| Type | Cold bending machine |

| Application | Perforated sheet making machine |

| Motor Power | 15kW |

| Overall Dimension | 9800mm *1500mm*1500mm |

| Weight | 10 tons |

| Customization Service | Available |