Condenser Rubber Ball Automatic Cleaning Device

Automatic condenser cleaning device for cleaning heat exchange tubes by injecting rubber balls

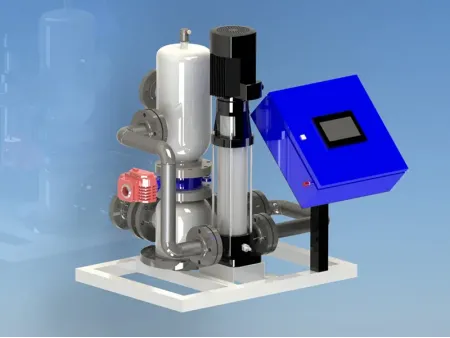

Maintaining the efficiency of heat exchange tubes is important to maintain its optimal performance, and the condenser tube cleaning device offers an innovative solution. It uses rubber balls to scrub the inner walls of condenser heat exchange tubes, effectively removing scale, dirt, and microbial films. The condenser cleaning device consists of a ball collector, ball injector, water pump, and control unit. By harnessing the power of water flow and friction, it ensures thorough cleaning without the need for chemicals or manual labor. The pressurized water pump sends the cleaning balls into the condenser, where they work continuously to keep the tubes clean and efficient.

Ideal for cleaning condensers in various air conditioning circulating water systems, including commercial buildings, industrial plants, hospitals, hotels, schools, and more.

- Microcomputer controls ensure the system operates automatically without manual intervention, with adjustable cleaning frequency based on water quality and maintenance needs

- No need to shut down the system; the main air conditioning unit continues to operate normally while the cleaning system works online

| Model | Condenser Unit Capacity (Ton of Refrigeration) (for reference only, subject to actual cooling water pipe diameter) |

| Below 200TR | |

| 200-500TR | |

| 300-500TR | |

| 500-800TR | |

| 600-1000TR | |

| 1000-1500TR | |

| Above 1500TR |

Constructed entirely of 304 stainless steel, the condenser tube cleaning system features DN50 flange connections. The ball injection flow rate is 20L/S, with a pressure rating of 16bar. It boasts an effective flow area that is four times greater than the connecting pipeline, ensuring minimal fluid resistance with a pressure loss of less than 5Kpa