Acrylic Recycling Pyrolysis Plant

1. Advanced Technique

The main function of the multifunction separation equipment is to remove the solid particles and liquid drops from the gas as much as possible, thus realizing gas-liquid-solid separation. This can ensure normal operation of oil refining pipelines and equipment sets.

2. Dedusting with High Efficiency

The flue dedusting system is equipped with bidirectional water flushing cyclone dedusting chamber to ensure that the flue emission meets the national emission standard.

3. Good Sealing Performance

Our acrylic recycling pyrolysis plant employs high-efficiency mixed fuel heating system composed of coal, fuel and non-condensable gas. After the purification of dust removal tower and industrial waste gas purification device, the waste gas will reach the national emission standard. The whole system has been tested to meet the highest standards in Europe and USA, and has passed EPI certificate.

4. Good Cooling Effect

The condenser has the following features: good cooling effect, compact structure, uneasy blockage, small flow resistance, easy cleaning etc. It can prevent the blockage caused by formation of dirt and scale on the pipe wall.

5. Energy-Saving and Environment-Friendly

The non-condensable gas produced in pyrolysis can be directly used as fuel for the pyrolysis furnace, thus producing large amount of heat energy. So the gas pollution can be prevented and the fuel can be saved as well.

6. Low Noise

The noise generated by the operation of the whole set of equipment is lower than 65 db. There is no generation of smoke and dust as well.

7. Wide Applications

The main pyrolysis furnace can be used for pyrolysis of waste tire, waste plastics, waste rubber, waste PMMA and some other materials.

Waste PMMA, PE (high price; mainly used to produce plastic particles), PET (transparent beverage bottles; try not to use it), PVC (water pipe), PP (disposable water cup; try not to use it) and various waste Nylon products.

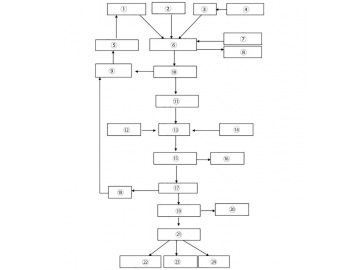

Shut the feeding sealing door after feeding. Start up the heating system. The mixed gas produced during pyrolysis will enter the multifunction separator. The heavy components will settle down and then enter the residual oil tank through oil pipeline. Then it will be pumped into the pyrolysis furnace for further pyrolysis. While the light components will go up and enter the condensing system. The condensed liquid oil will enter the oil-liquid separator through pipelines for oil-liquid separate measurement. The flue gas produced during the pyrolysis will enter the flue gas desulphurization and dedusting equipment through flue pipe for spray dedusting and cooling. Then it will be discharged into the flue gas purifier by induced draft fan, thus realizing harmless emission finally.

The carbon black generated by the pyrolysis will enter the production workshop of carbon black. The circulating water of the cooling system is provided by the cooling pond; the water of water seal, water tank of the vacuum pump and the dedusting tower is provided by the pump house. The water can be replenished under manual control during the system operation.

1. Hot water circulating pump

2. Flue gas desulphurization and dedusting equipment

3. Standard purification

4. Wind turbine

5. Funnel

6. Emission

7. Material to be pyrolyzed

8. Feeder

9. Pyrolysis furnace

10. Mechanical seal

11. Phase separator

12. Condensing system

13. Refined oil receiving tank

14. Gas burner

15. High temperature oil pump

16. Cooling tower

17. Power distribution cabinet

18. Crude oil receiving tank

19. Circulating water pool

20. Water pump

21. Aerator

22. Flame arrestor

23. Water sealed tank

24. Oil storage tank

1. Combustion heating system

2. Feeding system

3. Pyrolysis system

4. Cooling system

5. Circulating water system

6. Pressure and temperature alarming system

7. Electronic control system

8. Flue gas treatment environment protection system

9. Exhaust recovery system

The terminal products produced from waste plastics by pyrolysis oil production: plastic oil and carbon black.

Plastic oil: The plastic oil can also be called as fuel oil which can be sold directly, or used for deep treatment, fuels for boiler heating, bathing, restaurant, and floor tile making, or be processed to organic solvents or vehicle fuels by refining equipment.

Carbon black: The carbon black can also be sold directly as fuel. It can also be deep processed by carbon black refining equipment which can be divided into two types: one type of the equipment can produce terminal products of 300-1000 mesh which can be used to produce rubber and tire filler, another type of the equipment can produce terminal products of 1000-2500 mesh which can be used to produce industrial carbon black, printing ink etc. The carbon black produced by certain waste plastics has relatively low quality, but it can also be used as fuel.

| Model | Volume of the pyrolysis furnace | Pyrolysis furnace dimension mm | Coal consumption | Cooling water consumption | Noise dB (A) |

| 3.5 m3/furnace * 10 furnace | 1500*2000 | 100kg standard coal/t | 100t/h | ≤80 | |

| 6 m3/furnace * 7 furnace | 1600*3000 | 100kg standard coal/t | 100t/h | ≤80 | |

| 9 m3/furnace * 5 furnace | 2000*3000 | 100kg standard coal/t | 100t/h | ≤80 |

● Structure of main furnace: direct heating;

● System pressure: micro negative pressure;

● System cooling method: water circulation cooling;

● Installation: without foundation;

● Working mode: semi-continuous working;

● Installation period: 25 workdays.