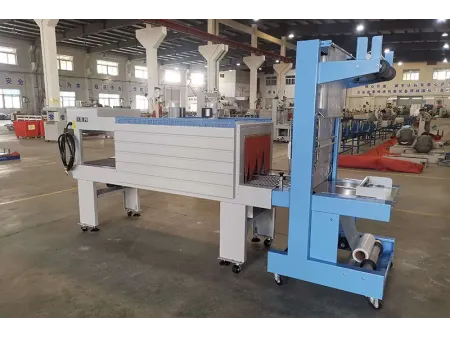

Automatic Shrink Sleeve Wrapping Machine

Request a Quote

LQ-XKS-2

Shrink packaging machine combining shrink tunnel and shrink bundler

Our automatic shrink sleeve wrapping machine combines a shrink tunnel with a shrink bundler, making it perfect for packaging beverages, beer, mineral water, pop-top cans, and glass bottles without a tray. Designed to handle single or combined products, this packaging system can integrate with production lines to automate feeding, film wrapping, sealing, cutting, shrinking, and cooling processes. It offers various packing modes, accommodating different bottle quantities such as 6, 9, 12, 15, 18, 20, or 24.

Main Components

Specifications

| Power Supply | AC 380V/50Hz |

| Compressed Air | 60L/min |

| Power | 18.5kW |

| Max. Package Size | 450mm×320mm×200mm |

| Max. Film Width | 600mm |

| Packaging Speed | 8-10pcs/min |

| Cutting Length | 650mm |

| Cutting Time | 1.5-3 seconds |

| Temperature Range | 150-250℃ |

| Film Thickness | 40-80μm |

| Shrink Tunnel Size | 1500mm×600mm×250mm |

| Machine Size | 3600mm×860mm×2000mm |

| Weight | 520kg |

Features

Shrink machine

- Built on advanced technology and international design standards, ensuring stable and reliable operation

- The conveyor belt can be set for left or right feed-in, providing flexibility in production layout

- Capable of packing 2, 3, or 4 rows of bottles with or without trays. Simply turn the switch on the panel to change the packing mode

- Uses a worm gear reducer, which ensures stable conveying and film feeding, enhancing the overall efficiency of the packaging process

Shrink tunnel

- Equipped with double blowing motors to ensure even heat distribution inside the tunnel, resulting in a smooth and professional shrink finish

- Features an adjustable hot air guide flow frame inside the tunnel, making the process more energy-efficient

- Utilizes solid steel rollers covered with silicone gel pipes and chain conveying, ensuring durability and consistent performance