Pressure Screen (Upward Flow)

Capacity: 15-300 T/D

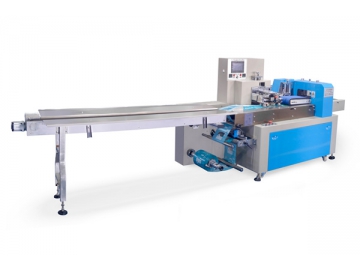

The UV series pressure screen is a new recycled pulp screening equipment that Huaxia developed for the paper industry. According to the characteristics of impurities in the pulp, this pressure screening machine is designed with an upward flow structure. It can be widely used for coarse and fine screening of various wastepaper pulp as well as pulp screening before going to the paper machine, and features an unmatched working performance and reliability.

Features of the Pressure Screen

1. The upward flow structure avoids pipe intersections in the pressure screen.

2. A steady open base design ensures easy maintenance and change of the belt and belt pulley.

3. The large power drive part of the sealing device on the pulp screen can be installed and dismantled integrally, reducing the downtime for maintenance.

4. It is easy to clean, adjust, check, and dismantle the screen cylinder and rotor.

5. The pressure screen can be equipped with different cylinders, including the plain and corrugated screen cylinders.

6. According to pulp properties, the stock preparation equipment can be equipped with various kinds of rotors.

7. The maximum pressure is 875Kpa and can meet various application conditions.

| Model | | |||||||

| Screen mesh size (mm) | Ø1.1-Ø5 | |||||||

| Screen cut size (mm) | H0.15-1 | |||||||

| Screening area (m²) | 0.3 | 0.6 | 0.8 | 1.2 | 1.5 | 2.0 | 2.5 | 3.0 |

| Cylinder specifications (mm) | Ø407 ×258 | Ø600 ×311 | Ø600 ×425 | Ø600 ×635 | Ø600 ×800 | Ø756 ×838 | Ø756 ×1048 | 920 ×1048 |

| Inlet consistency (%) | 0.2-6 | |||||||

| Inlet diameter (mm) | Ø150 | Ø200 | Ø200 | Ø200 | Ø300 | Ø325 | Ø350 | Ø350 |

| Outlet diameter (mm) | Ø150 | Ø200 | Ø200 | Ø200 | Ø300 | Ø325 | Ø350 | Ø350 |

| Top rejects discharge hole diameter | Ø80 | Ø100 | Ø100 | Ø100 | Ø100 | Ø125 | Ø125 | Ø125 |

| Capacity (T/D) | 15 -30 | 30 -50 | 40 -70 | 60 -100 | 90 -180 | 120 -240 | 150 -300 | 200 -400 |

| Power (KW) | 22KW /4 | 30KW /4 | 37KW /4 | 55KW /4 | 75KW /4 | 90KW /4 | 110KW /4 | 132KW /4 |

Structure of the Pressure Screen

1. Screen Cylinder

The screen cylinder comes with a screen cut width of 0.15mm. We use water jet cutting technology to put a slot on the steel plate that is 8mm in width, forming excellent screen holes and a burr free notch. It will not generate stress and cracks caused by mechanical milling. In addition, the hard chrome plating process is available for improving wear resistance.

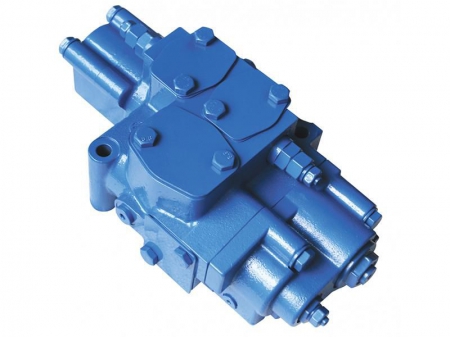

2. Rotor with Wings

The fine screening rotor comes with 3-4 wings, which ensures no vibration is generated during high speed rotation of the rotor. The rotor is mounted on the main shaft with the wings mounted on it through the screw rod. The gap between the rotor wing and the screen cylinder can be adjusted. A coarse screening rotor features a drum type rotor wing structure which can protect the rotor from being wound by impurities and can ensure normal work.

3. Housing

The housing of the pressure screen is composed of the upper cover and the screen body. It is designed with a pulp inlet pipe at the lower part of the body, and an outlet pipe at the top part of the body. On the upper cover, it comes with an injection discharge hole and washing hole.

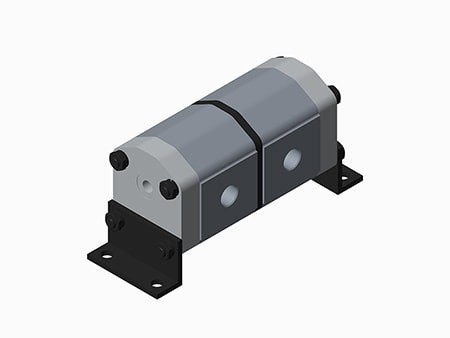

4. Drive Unit

The drive unit consists of the motor, V-belt, main shaft and bearing.

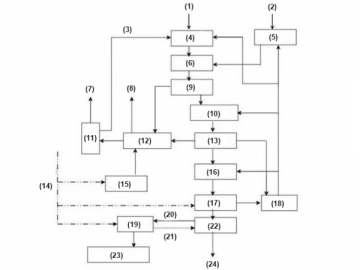

Working Principle of the Pressure Screen

It is well known that impurities in recycled pulp include both light and heavy types. A traditional pressure screen employs the use of a top feed and bottom discharge structure. When screening chemical pulps, this structure can reduce impurity dwelling time in the screen as the gravity and mass of the impurities are larger than a single fiber. When screening recycled pulps that contain a large number of light impurities however, it will extend the dwelling time of the impurities in the screen, which reduces the screening efficiency and intensifies the wear on the rotor and cylinder.

The UV series pressure screen comes with an upward flow structure. Specifically, it features a bottom pulp feeding, bottom heavy injection discharging, and top heavy injection discharging structural design, which effectively solves the aforementioned problem. Light impurities and air in the pulp naturally go up, and are discharged from the top. Heavy impurities will rapidly sink to the bottom and discharge once they enter the machine. In this case, the dwelling time of the impurities in the pressure screen can be reduced, improving screening efficiency, and it can also protect the rotor and cylinder from becoming damaged by heavy impurities.