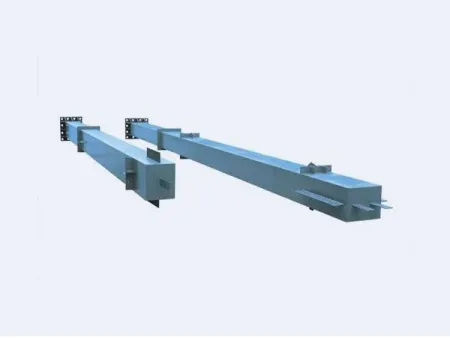

Steel Box Column & Beam

Request a Quote

Steel box columns and beams are named for their closed, box-shaped cross section, which resembles a hollow steel box. In steel structure construction, they are mostly used as primary load-bearing beams or columns, particularly in projects with higher structural demands. With their closed sectional form, steel box components offer excellent load transfer performance, making them suitable for both vertical and horizontal structural applications.

Manufacturing process

Steel box columns are formed by welding four steel plates into a closed section. The manufacturing process is generally similar to that of welded H-sections and is completed entirely in a controlled factory environment. The production sequence includes:

- CNC cutting of steel plates

- Edge preparation through flame cutting or edge planing

- Section assembly and alignment

- Submerged arc welding; electroslag welding is used where required, such as for corbels or special structural demands

- Pre-correction when welding deformation is anticipated

- Installation of small fittings with riveting and component identification marking

- Manual welding for detailed joints

- Dimensional correction and straightening

- Shot blasting for surface cleaning

- Painting, including marking of reference elevation lines and centerlines

Structural characteristics

- Closed section formed by four steel plates: Steel box columns and beams consist of four steel plates connected by corner welds. Depending on strength requirements, these welds are designed as partial or full penetration welds to ensure long-term structural performance.

- Internal diaphragms for load transfer: Transverse diaphragms are installed inside the box section to improve load distribution and local stability. Both the outer plates and internal diaphragms are assembled using controlled processes to ensure uniform welding quality.

- Reliable connection details: Connection plates are arranged on the outer surface of the box column at each floor level to facilitate beam connections. Column-to-column connections are typically achieved through a combination of tight fit-up and welding, ensuring stable load continuity.

Why steel box columns and beams are used in heavy-load projects?

- High load capacity and overall stability: The closed cross-section provides strong resistance to compression, bending, and torsion, making steel box columns and beams well suited for high-rise buildings and heavy-load steel structures.

- Suitable for large spans and tall structures: These steel components are widely applied in high-rise steel buildings, heavy industrial workshops, and special structural projects requiring enhanced stiffness and stability.

- Factory-controlled production process with proven quality: From cutting and welding to straightening and surface treatment, all processes are completed in the factory. This ensures dimensional accuracy, consistent weld quality, and reliable quality traceability.