Automatic Flatbed Die Cutting and Creasing Machine with Stripping Unit (Heavy Duty)

- Max. Die Cutting Size (L×W) 1060×780 mm

- Die Cutting Accuracy ±0.1mm

- Max. Speed 7000 sheets/h

- Max. Die Cutting Pressure 700t

This powerful, fully automatic flatbed die-cutting and creasing machine combines heavy-duty die cutting with automated waste stripping, specifically engineered for demanding industrial packaging applications. It precisely die-cuts thick and rigid materials and efficiently removes waste, streamlining the entire process from accurate feeding and high-speed die cutting to precise stripping and neat delivery.

- 1060 Dimensional Drawing

- 1060 Dimensional Drawing

- 1450 Dimensional Drawing

- Paperboard

- Corrugated Cardboard

- PVC Sheet

- White Cardboard

-

- Pneumatic Quick-Lock for Die Cutting Chase Achieves rapid locking to ensure stability during the die cutting process.

-

- Non-stop Sheet Feeding and Collection Enables continuous, automatic paper feeding and collection to maximize production efficiency and minimize downtime.

-

- Pneumatic Sampling Facilitates on-the-fly sample checks during production without interrupting the process, ensuring consistent product quality.

-

- Automatic Lubricating System Provides smooth operation of all mechanical components, reducing friction and extending the machine's service life.

-

- Electric Pressure Adjustment Automatically adjusts pressure to suit different materials, ensuring precise die cutting performance.

-

- Automated Stripping Streamlines production by efficiently removing waste material.

- Feeder

Equipped with a high-precision four-suction, five-feed feeder head, this system accommodates thin paper, paperboard, and corrugated cardboard, ensuring smooth and consistent feeding even at high speeds. The integrated gantry-type pre-feed mechanism alternates between the main and auxiliary feed tables, enabling continuous, non-stop production.

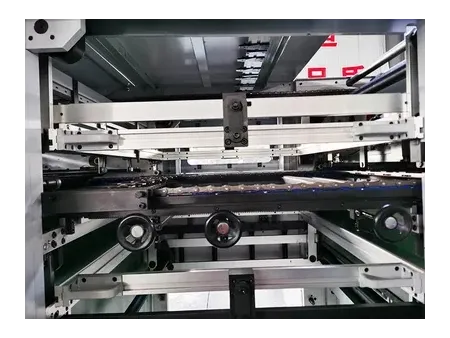

- Feeding System

Utilizes an imported flat conveyor belt to guarantee stable sheet transport. An optional vacuum feeding system further enhances stability—particularly when processing thin materials—ensuring consistent and reliable performance.

- Die Cutting Unit

Features a deformation-resistant, heat-resistant cast iron honeycomb plate and a pressure adjustment system with 12 independently controlled heating zones. This design guarantees an effective embossing and die cutting effect for heavy materials.

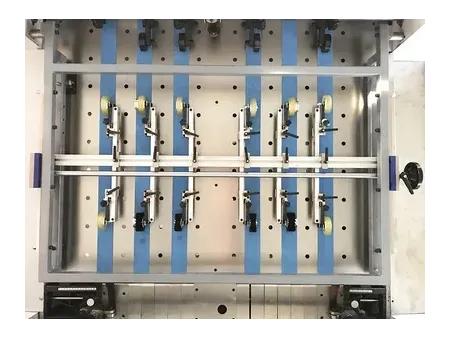

- Waste Removal / Stripping System

Employs a three-frame design (upper, middle, and lower) to deliver stable, precise, and powerful waste stripping. Based on production requirements, you can select between needle stripping or template stripping. The centrally positioned stripping template allows for easy changeover and accurate, smooth operation.

- Delivery Station

Uses a brush and rear air-blowing system to maintain stable sheet alignment. An electric auxiliary collection system supports continuous production, while the pneumatic sampling function enables real-time quality checks without halting production. An optional counting and marking (tab insertion) feature is available for added efficiency.

- Vacuum Pump

The German-engineered BECKER vacuum pump, combined with internationally recognized electrical and drive components (ABB, SMC, iWiS, Siemens, Mitsubishi Electric, Fuji Electric, IDEC, Yaskawa, OMPI, BECKER, etc.), guarantees die-cutting accuracy and reliable performance. The industrial air-conditioning system for the electrical cabinet maintains a consistent temperature, ensuring stable and continuous operation of the electrical components.

- HMI Interface

The HMI interface allows operators to monitor real-time machine status, display fault notifications, and access troubleshooting methods, enhancing operational ease and workflow management.

To maintain optimal performance and longevity of your machine, we recommend using genuine HFM consumables. We offer a complete range of high-quality replacement parts: Stripping pin, sliding plate, lower pin locking block, rubber wheel, timing belt, brush wheel, gripper bar, movable gripper.