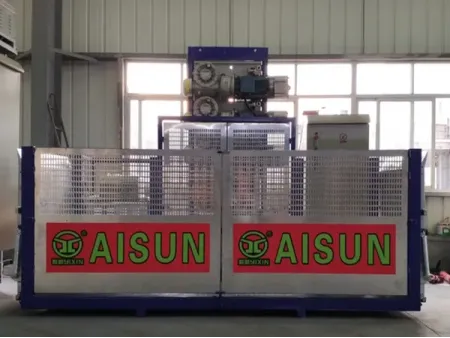

Construction Hoist

Request a Quote

| Quotation Details: NO.141004-1 | ||||

| Model No. | Minimum Order Quantity | Brief Description | ||

| | 1 set | Usage | Personnel and material hoist for use at construction sites | |

| Erection height | 72m (48 mast sections) | |||

| Cage/Elevator car | Perforated steel plate/Galvanized perforated steel plate | |||

| Motor power | 2 x (2 x 11) kw Jinnuo Brand, Shanghai China) | |||

| Safety brake | SAJ4.0-1.2 (SRIBS brand, Shanghai China) | |||

| Power supply | 380v/50hz (or as per customer requirements) | |||

| Main electrical elements | Schneider(foreign brand) | |||

| Rated lifting speed | 33m /min | |||

| Rated Loading capacity | 2 x 1000kg Double cage | Wall tie length & Qty | 2.8m -3.2m 9 pieces | |

| Cage Size(L x W x H) | 3 x 1.5 x 2.2M (Dimensions) | Mast section weight | 150kg | |

| Size of mast section | 650 x 650 x 1508mm Galvanized ( Ø76 x 4.5mm Seamless pipe) | Total weight | 12800kg /set | |

| FOB Qingdao Port | USD31,500 72M Height | Package | 1 x 40HQ 1 x 20GP | |

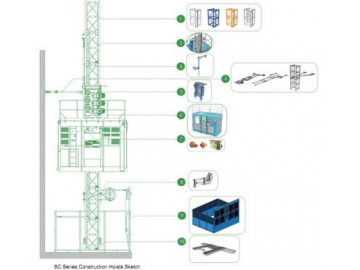

| Construction Elevator Details | |||||||

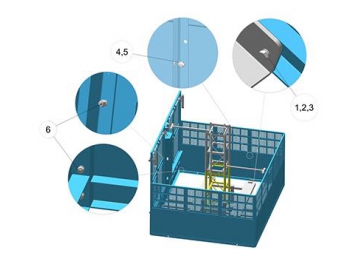

| 1 | Cage | Cage Dimension(L x W x H) | 3m x 1.5m x 2.2m | ||||

| Roof and base plate | Checked steel plate | ||||||

| Sidewall | Upper half | Perforated aluminum | |||||

| Lower half | Solid aluminum | ||||||

| Doors materials | Perforated steel plate | ||||||

| Sliding door with mechanical and electrical interlock | |||||||

| Main girder materials | Bent steel plate Q235 and steel profile | ||||||

| Surface coating | Electrostatic spray painting (orange, red or blue) | ||||||

| 2 | Ground Enclosure | Materials | Perforated steel plate, galvanization and electrostatic spray painting | ||||

| Door | Sliding door with mechanical and electrical interlock | ||||||

| Height | 1.8-2.0m | ||||||

| 3 | Mast sections | Dimensions | 650 x 650 x 1508m | ||||

| Steel grade | Steel plate Q235,seamless pipe | ||||||

| Bolts | 10.9 | ||||||

| Surface treatment | Hot dip galvanized | ||||||

| 4 | Tie-in | Adjustable intervals | 2.8m to 3.2m horizontally and 6m-9m vertically | ||||

| Tilt angle | ± 8 ° | ||||||

| 5 | Concrete Insert | M27 x 600 4 pieces each set and Foundation base metal | |||||

| 6 | Safety Device | Safety Brake | SAJ4.0-1.2 SRIBS brand (Shanghai, China) | ||||

| Overload Limit/Load Cell | |||||||

| Top limit, bottom limit, speed governor,3-Phase Cut-off | |||||||

| Emergency Cut-off. | |||||||

| Mechanical and electrical interlock inside and outside door. | |||||||

| Phase loss protection | |||||||

| Alarm, spring buffer | |||||||

| 7 | Drive Mechanism | Motor | Spec. | 11kw, JULI brand (Shanghai, China) | |||

| Class | IP55 | ||||||

| Speed Governor | Spec. | Cylindrical Worm Gear (with angled teeth)TCW144 Ratio: 1:16 | |||||

| 8 | Electrical system | Main Contactor | Schneider brand | ||||

| Inverter | None,(CAN300 INOVANCE BRAND) | ||||||

| Power Source | 380v/50hz (Or as per customer requirements) | ||||||

| 10 | Lifting speed | 33m/min | |||||

| 11 | Max. Erection Height | 150m | |||||

| 12 | Cable | 20mm2 | |||||

| Commercial Terms | |

| Remarks | The price does not cover installation fees. |

| Payment Terms | 30% TT advance payment prior to production. The rest should be paid off by TT before delivery. |

| Production Period | Within 10 working days after receiving 30% advance payment. |

| Price Validity | November 30, 2014 |

| Warranty Period | 1 year from delivery date |

| After-sale service | We provide free spare parts with equipment and send over technicians for maintenance when necessary. |

| Installation guide and charges | 1) The seller will send one of her experienced engineers to the Buyer's site to help completing installation works and training operators upon buyer request. 2) The Buyer is responsible for the following: A. Arrange accommodations and travels. B. Pay round trip airline tickets; Pay the engineer USD60 per working day as allowance. C. Chinese interpreter ensures effective communication and improved working efficiency. D. Send over an installation team( 4-6 people)responsible for installation works. E. Ensure the safety of the engineer in buyer's Country 3) On-site prep works should be done properly. Customers should bear all related costs if installation is delayed due to their fault. The buyer has to fill in an installation contact form provide by the seller and fax it to the seller to ensure the preparation work is well done. Before the seller's engineer arrives at the site, all prep work should be done. If not, all related costs incurred due to installation delay should be paid by the customer. 4. The buyer needs to discuss with the seller on installation schedule. |

| Spare parts provided for free along with shipment | Guide rollers: 4 sets Counter rollers: 2 sets Gear:1 set Phase sequence: 1 Limit switch: 2 sets Rectifier: 1 set Contactor(380v):1 set Rack Pins:20 sets |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos