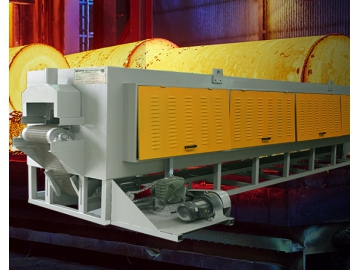

Vacuum Heat Treatment Furnace

Benefits of Vacuum Furnace

1. Heat treatment furnace is properly configured to ensure uniform heating, minimizing power consumption.

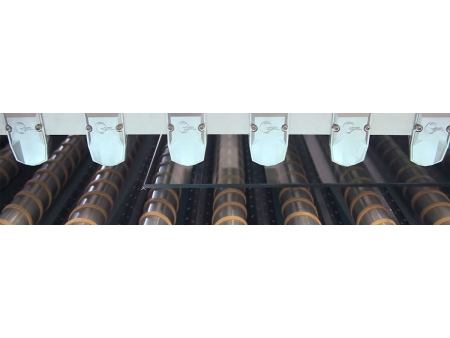

2. Oil mixer tumbles the oil gently which allows workpiece to cool down gradually thereby minimizing hardening distortion due to abrupt temperature change. Both the vacuum level and gas pressure are adjustable to suit the cooling needs of various materials.

3. Cooling gas jets out into the chamber for fast, even quenching.

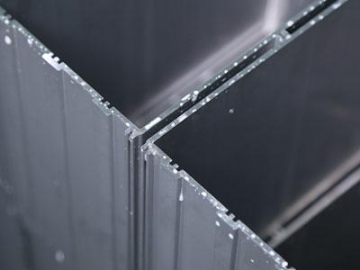

4. Insulated gate valve comes with durable seals and locks heat within the vacuum furnace chamber.

5. This industrial furnace contains few moving parts for reliable operation.

6. Furnace cover is sealed with robust locking ring to maintain a negative or positive pressure in the chamber.

Applications

1. High pressure gas quenching or oil quenching of alloy steel, high speed steel, tooling steel, bearing steel, elastic alloy, and stainless steel, etc.

2. Heat treats magnetic materials.

3. Brazing, annealing and sintering of alloy steel, alloy structural steel, tooling steel, high speed steel, bearing steel, elastic alloy, and stainless steel, etc.

| Specifications Model No. | ||

| Effective working area | 550× 400 × 400 (mm) | 900×600×450mm |

| Installed Furnace Capacity | 150 Kg | 300Kg |

| Maximum Temperature | 1300℃ | 1300℃ |

| System Configurations | ZLD-600/2X-70 | ZLD-600×2.2X-70×2 |

| Furnace Temperature Change | ±5℃ | ±5℃ |

| Maximum Vacuum | 4×10 -1 (Pa) | 4×10 -1 (Pa) |

| Pressure Increment | 0.67(P/h) | 0.67(P/h) |

| Heating Power | 65 KW | 100KW |

| Compressed Gas Pressure | <2bar | <2bar |

| Compressed Air Pressure | 0.4~0.8MPa | 0.4~0.8MPa |

| Water Cooling System | Water Pressure /Water Temperature: ≤25℃/≥0.25MPa (Prepared by clients) | Water Pressure /Water Temperature: ≤25℃/≥0.25MPa (Prepared by clients) |

.jpg)