Casting and Molding

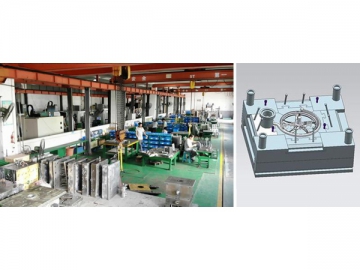

Tokyu Automatic Molding Line

We complete all casting procedures in-house, which enables us to perform quality controls and inspections conveniently. Our performance casting equipment further ensures the quality of our range of sand casting parts.

1. Casting Procedure

Raw materials are melted in a medium frequency, electric furnace, where the temperature of the metal rises to about 1,600°C. At this point, our quality control team analyzes the chemical properties of the hot metal and—if it passes the test—we pour it into the sand mold. Once cooled, the mold is removed for a final inspection.

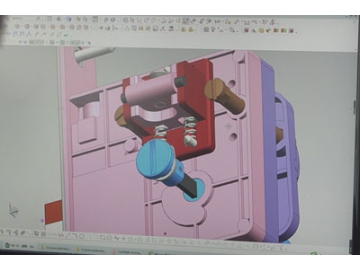

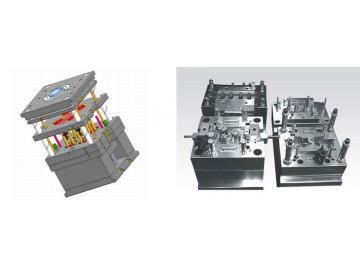

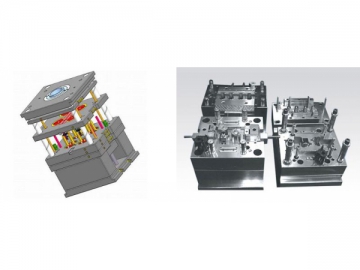

2. Casting Equipment

In 2012, we began using the Japanese Tokyu automatic molding line. With two automatic molding positions, the molding doubles our output by making 100 boxes per hour. The sandbox’s size is 600mm×700mm with an adjustable height of 170mm, 210mm or 250mm. A year later, we improved and updated resin-bonded sand processing, sand preparation and core making equipment.

Our casting equipment has the following advantages:

1. The molding sand is shot vertically from the top of our casting equipment, allowing for a more thorough and unblemished filling process. We also have the more traditional horizontal casting processing method, which can be used in a wide range of projects.

2. Strong guiderails and centering pins mounted on the frame of our casting equipment ensure the accuracy of our production process and minimize the errors of spotted or uneven metal castings.

3. Adjustable heights and compaction pressures allow us to make different iron castings and work on a number of specially designed projects.

4. Our casting equipment uses simple plug-in amounts, allowing us to easily and quickly change the mold of our casting for a more efficient production process.

- Model Warehouse

- Greensand Molding Machine

- Resin-bonded Sand Molding Machine

- Coated Sand Core Making