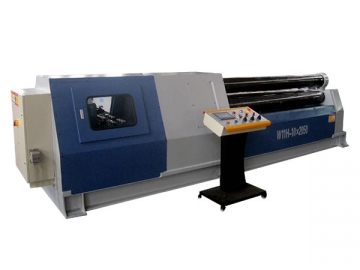

3 Roll Plate Bending Machine, Universal Type

Three roll plate bending machines (universal type) manufactured by Yeshun are capable of bending plates of 2 to 200mm thicknesses and widths of 1,000 to 10,000mm.

Features:

1. The top roll is designed in a drum shape. A support roll is installed below the bottom roll to help bend a perfect cylinder from thick and thin plates.

2. Special bending technology is used, including high precision edge pre-bending, and digital control for the bending process.

3. This universal plate bending machine can bend plates into different shapes, including various letters, such as O, U, and R.

4. The roll plate bending machine is equipped with a cone bending device for easy cone bending.

5. The welded frame and simple foundation make it easy to move the machine.

6. An economic digital display type or CNC digital control type are optional according to customer requirements.

7. This machine is CE and ISO9001:2008 certified.

| Model | Pressure of Top Roller (T) | Max. Bending Thickness (mm) | Pre-bending Thickness (mm) | Max. Bending Width (mm) | Top Roll Diameter (mm) | Power of Motors (KW) | ||

| For driving | For hydraulic device | For movement | ||||||

| 25 | 4 | 3.5 | 2500 | 200 | 4 | 2.2 | 1.1 | |

| 30 | 6 | 5 | 2500 | 210 | 4 | 2.2 | 1.1 | |

| 37 | 8 | 6.5 | 2000 | 210 | 4 | 2.2 | 1.1 | |

| 37 | 8 | 6.5 | 2500 | 235 | 5.5 | 2.2 | 1.1 | |

| 37 | 10 | 8 | 2000 | 235 | 5.5 | 2.2 | 1.1 | |

| 55 | 10 | 8 | 2500 | 250 | 7.5 | 4 | 1.1 | |

| 65 | 12 | 10 | 2000 | 250 | 7.5 | 4 | 1.1 | |

| 75 | 12 | 10 | 2500 | 265 | 7.5 | 4 | 1.5 | |

| 75 | 12 | 10 | 3000 | 290 | 11 | 4 | 1.5 | |

| 75 | 16 | 13 | 2000 | 265 | 7.5 | 4 | 1.5 | |

| 100 | 16 | 13 | 2500 | 300 | 15 | 5.5 | 1.5 | |

| 130 | 16 | 13 | 3000 | 330 | 15 | 5.5 | 2.2 | |

| 100 | 20 | 16 | 2000 | 300 | 15 | 5.5 | 1.5 | |

| 130 | 20 | 16 | 2500 | 330 | 15 | 5.5 | 2.2 | |

| 160 | 20 | 16 | 3000 | 380 | 18.5 | 7.5 | 2.2 | |

| 230 | 20 | 16 | 4000 | 440 | 30 | 11 | 4 | |

| 190 | 25 | 20 | 2500 | 380 | 22 | 7.5 | 4 | |

| 230 | 25 | 20 | 3000 | 410 | 30 | 11 | 4 | |

| 270 | 25 | 20 | 4000 | 490 | 30 | 11 | 4 | |

| 230 | 30 | 25 | 2500 | 410 | 30 | 11 | 4 | |

| 270 | 30 | 25 | 3000 | 450 | 30 | 11 | 4 | |

| 380 | 30 | 25 | 4000 | 550 | 45 | 22 | 5.5 | |

| 320 | 35 | 28 | 2500 | 450 | 30 | 11 | 4 | |

| 380 | 35 | 28 | 3000 | 510 | 45 | 22 | 5.5 | |

| 380 | 40 | 32 | 2500 | 500 | 45 | 22 | 5.5 | |

| 430 | 40 | 32 | 3000 | 540 | 55 | 22 | 7.5 | |

| 540 | 40 | 32 | 4000 | 630 | 55 | 22 | 11 | |

| 540 | 45 | 36 | 3000 | 590 | 55 | 22 | 11 | |

| 430 | 50 | 40 | 2500 | 580 | 55 | 22 | 7.5 | |

- Movable control panel, with remote control

- Siemens electrical appliances

- Hydraulic tipping device (for easy removal of the work piece)

- Support roll of the bottom roll (for compensation of the deflection of the bottom roll)