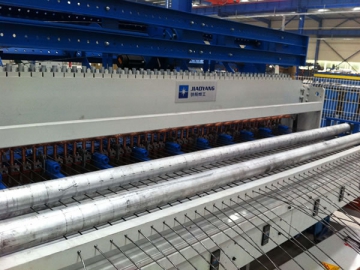

Construction Mesh Welding Machine

Wire Mesh Machine / Mesh Welder / Wire Welder

Features of the Construction Mesh Welding Machine

1. The main structure of the welding machine utilizes a motor driven, spring weighted design, minimizing operating costs.

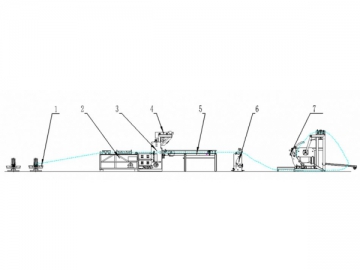

2. Cross wires are pre-straightened and cut while line wires are fed from coils.

3. The welding function of the machine is PLC controlled for maximum precision, allowing for continuous production of wire mesh sheets or rolls.

4. Welding process is controlled synchronously, allowing the welding transformers to work simultaneously or separately.

5. Welding materials handled include, hot-rolled ribbed bar, cold-rolled ribbed bar, hot-rolled plain bar, cold-rolled plain bar, etc.

6. It is very easy to adjust the working specifications. The current and cross wire spacing is set by touch screen.

Technological processes of the Construction Mesh Welding Machine Technical parameters of the Construction Mesh Welding Machine

Technical parameters of the Construction Mesh Welding Machine | Model | GWCD1200D (3-6.5) | GWCD1600D (3-6.5) | GWCD2100D (3-6.5) | GWCD2500D (3-6.5) |

| Welding spots number | 24 | 32 | 40 | 48 |

| Width of mesh | ≤1200 mm | ≤1600 mm | ≤2100 mm | ≤2500 mm |

| Wire diameter | 3-6.5 mm | 3-6.5 mm | 3-6.5 mm | 3-6.5 mm |

| Transverse bar spacing | ≥50mm | ≥50 mm | ≥50 mm | ≥50 mm |

| Longitudinal bar spacing | 50-200 mm | 50-200 mm | 50-200 mm | 50-200 mm |

| Min. power | 160KVA | 160KVA | 160KVA | 160KVA |

| Optimal power | 400 KVA | 500 KVA | 630 KVA | 800 KVA |

| Welding speed | 60-80t/min | 60-80t/min | 60-80t/min | 60-80t/min |

| Control system | PLC/SCM | PLC/SCM | PLC/SCM | PLC/SCM |

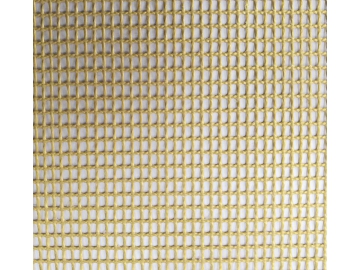

Applications

The wire welder is primarily used to produce welded wire mesh that is utilized in construction applications (geothermal meshes, seedbed mesh, etc.)