Label Die Cutter

Request a Quote

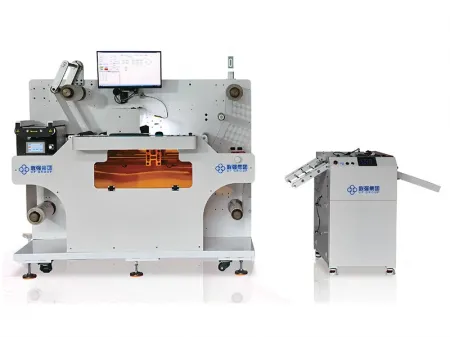

LQ-MD 330S

Label die cutting and slitting machine

This label die cutter is designed to improve your label production with consistent precision, stability, and increased speed. Its robust structure is more durable than many other die cutters, leading to higher cutting accuracy and improved stability during operation. This label die cutter is designed to make label production processes easy and convenient, providing accurate cuts for both simple and complex projects. With its innovative design, precise cutting mechanisms, and user-friendly features, this die cutting machine is a valuable asset for businesses that need precise and efficient label cutting.

Applications

Specifications

| Cut Label Width | 60-320mm |

| Cut Label Length | 10-900mm |

| Die Cutting Speed | 15m/min |

| Number of Cutting Heads | 4 |

| Number of Split Knives | 5 (depending on demands) |

| Die Cutting Method | Imported alloy die cutting blade |

| Die Cutting Accuracy | 0.1mm |

| Splitting Speed | 30m/min |

| Split Size | 20-320mm |

| File Format | PLT |

| Machine Size | 1600×1200×1800mm |

| Machine Weight | 1500kg |

| Power | 2600W |

Features

- The die cutter's strong and stable design enhances cutting accuracy and stability, allowing for quicker operations. This design is especially beneficial for high-volume production where consistent precision is important

- Unlike standard motors found in similar die cutting equipment, this die cutter uses a high-precision ball screw motor. This motor type enhances cutting accuracy and has a longer lifespan, ensuring steady performance and reducing the need for frequent maintenance.

- The adaptive tension buffer control mechanism maintains stable tension across the material's width. This prevents uneven force and material distortion, ensuring uniform cuts and consistent quality, no matter the material width

- The modular design of the control system makes maintenance and replacements straightforward. Clear and stable circuit connections simplify troubleshooting and repairs, allowing for quick component changes which reduce downtime and boost overall cutting efficiency.