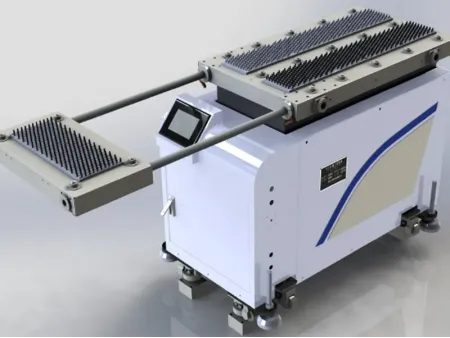

CNC Press Brake Sheet Follower

Request a Quote

Sheet following system for assisting press brake operator to effortlessly handling heavy and large parts

Sheet following system for assisting press brake operator to effortlessly handling heavy and large parts

Key Specs

- Lifting weight: 100kg-300kg

- Lifting angle: 60°

- Working table length: 970mm-1450mm

- Features

- Specifications

- Components

A sheet follower serves as an auxiliary supporting device for press brakes. Compatible with any brand of press brake, it can support large sheet metal materials during bending, ensuring continuous and circular movement to prevent material sagging. This system significantly reduces labor requirements, distributes stress evenly across the sheet, and maintains high bending accuracy.

Applications

The sheet follower is ideal for handling elevator metal parts, aluminum curtain walls, and metal environmental protection equipment. It is also used in the production of large kitchen utensils and metal storage cabinets, supporting complex bending tasks.

Features

- Labor-Saving Efficiency

Enhances productivity by minimizing manual handling requirements. - Synchronized Operation

The follow-up device automatically adjusts with the bending cycle, synchronizing perfectly with the press brake to support the plate throughout the bending process. - Mobility and Flexibility

Features a floor-mounted structure that can be easily relocated as needed. - Advanced Control Systems

Equipped with an independent PLC and an electrical control system, integrating magnetic scale feedback for precise movement. - Servo Motor Technology: Utilizes a computer-controlled servo motor that forms a closed loop to ensure the accuracy of the follow-up action.

Specifications

| Model | |||

| Lifting weight (kg) | 100 | 200 | 300 |

| Lifting angle (°) | 60 | 60 | 60 |

| Working table length (mm) | 970 | 1100 | 1450 |

| Length extension (mm) | 2000 | 2300 | 2600 |

| Working table width (mm) | 570 | 750 | 800 |

| Height adjustment (mm) | 120 | 120 | 120 |

| Forward collision avoidance (mm) | 150 | 150 | 220 |

| Accuracy (°) | ±0.3 | ±0.3 | ±0.3 |

| Transmission mode | Connecting rod ball screw | Connecting rod ball screw | Connecting rod ball screw |

Components

Details

Types

- Sheet follower for electric press brake

- Sheet follower for up-acting press brake

- Sheet follower for torsion bar press brake

- Sheet follower for CNC press brake

Working Principle

- Vertical Adjustment

Utilizes a servo motor that powers a pulley system to drive a screw rod. This action moves the slide vertically, aligning the upper surface of the follower flap with the upper plane of the press brake's lower die, accommodating various die heights. - Synchronization Mechanism

Another servo motor is mounted on the slide, which rotates a screw rod via a belt wheel. The screw rod features a longitudinal row of keyways with a latch installed at the upper dead center. The rotation of the screw translates into vertical movement along its own keyway under the latch's action, ensuring that the follower flap remains close to the metal plate throughout the bending process, providing synchronized support.

Standard Configurations

- Touch screen: Delta (Taiwan)

- Servo motor: Delta (Taiwan)

- Touch screen PLC: Kunluntongtai (Mainland China)

- Magnetic scale: GIVI (Italy)

- AC contactor, thermal relay: Schneider (France)

- Circuit breaker, push button: Schneider (France)

- Miniature relay: Schneider (France)