Flexo Printer Slotter Die Cutter (260pcs/min), YKW 1224 Series

Why you choose this machine, what this machine can do for you ?

1. Our company has developed this series of multifunctional printing machine with a maximum DPI of 600-700 for high precision printing applications.

2. This equipment functions as a printing, slotting and die cutting machine. The flexo printer slotter die cutter features an output of 260pcs/min, which greatly increases efficiency and reduces labor costs.

3.There are 6 color choices for the flexo printer slotter die cutter.

| NO | Parameter name | Unit | Specification |

| YKW/YKW1/YKW2-920 | |||

| 1 | Design speed | Pcs/min | 300 |

| 2 | Max feeding paperboard size | mm | 900x2000 |

| 3 | Mini feeding paperboard size | mm | 260x600/300x600/350x600 |

| 4 | Feeding paper by skip | mm | 1200x200 |

| 5 | Maxi printing area | mm | 900x1960 |

| 6 | Over printing precision | mm | ± 0.5/ ± 0.5/ ± 0.3 |

| 7 | Printing plate standard thickness | mm | 7.2 |

| 8 | Printing paperboard thickness | mm | 2-11 |

| 9 | Printing roller axle circular adjust | degree | 360 ° |

| 10 | Printing roller axial adjust | mm | ± 10 |

| 11 | Slotting precision | mm | ± 1 |

| 12 | Mini slotting space | mm | 130 |

| 13 | Maxi slotting depth | mm | 260 |

| 14 | Die cutting precision | mm | ± 1 |

| 15 | Die cutting knife roller axial adjust | mm | ± 10 |

| 16 | Total power(three/four/five/six color) | mm | YKW 45/55/60/65 YKW1/2 75/83/96/114 |

| Note: all above total power parameter does not include the drying configuration | |||

| NO | Parameter name | Unit | Specification |

| YKW/YKW1/YKW2-924 | |||

| 1 | Design speed | Pcs/min | 280 |

| 2 | Max feeding paperboard size | mm | 900x2400 |

| 3 | Mini feeding paperboard size | mm | 260x600/300x600/350x600 |

| 4 | Feeding paper by skip | mm | 1200x2400 |

| 5 | Maxi printing area | mm | 900x2360 |

| 6 | Over printing precision | mm | ± 0.5/ ± 0.5/ ± 0.3 |

| 7 | Printing plate standard thickness | mm | 7.2 |

| 8 | Printing paperboard thickness | mm | 2-11 |

| 9 | Printing roller axle circular adjust | degree | 360 ° |

| 10 | Printing roller axial adjust | mm | ± 10 |

| 11 | Slotting precision | mm | ± 1 |

| 12 | Mini slotting space | mm | 130 |

| 13 | Maxi slotting depth | mm | 260 |

| 14 | Die cutting precision | mm | ± 1 |

| 15 | Die cutting knife roller axial adjust | mm | ± 10 |

| 16 | Total power(three/four/five/six color) | mm | YKW 45/55/60/65 YKW1/2 75/83/96/114 |

| Note: all above total power parameter does not include the drying configuration | |||

| NO | Parameter name | Unit | Specification |

| YKW/YKW1/YKW2-1224 | |||

| 1 | Design speed | Pcs/min | 260 |

| 2 | Max feeding paperboard size | mm | 1200x2400 |

| 3 | Mini feeding paperboard size | mm | 300x600/350x600/400x600 |

| 4 | Feeding paper by skip | mm | 1500x2400 |

| 5 | Maxi printing area | mm | 1200x2360 |

| 6 | Over printing precision | mm | ± 0.5/ ± 0.5/ ± 0.3 |

| 7 | Printing plate standard thickness | mm | 7.2 |

| 8 | Printing paperboard thickness | mm | 2-11 |

| 9 | Printing roller axle circular adjust | degree | 360 ° |

| 10 | Printing roller axial adjust | mm | ± 10 |

| 11 | Slotting precision | mm | ± 1 |

| 12 | Mini slotting space | mm | 130 |

| 13 | Maxi slotting depth | mm | 300 |

| 14 | Die cutting precision | mm | ± 1 |

| 15 | Die cutting knife roller axial adjust | mm | ± 10 |

| 16 | Total power(three/four/five/six color) | mm | YKW 51/60/69/78 YKW1/2 85/94/103/114 |

| Note: all above total power parameter does not include the drying configuration | |||

| NO | Parameter name | Unit | Specification |

| YKW/YKW1/YKW2-1228 | |||

| 1 | Design speed | Pcs/min | 230 |

| 2 | Max feeding paperboard size | mm | 1200x2800 |

| 3 | Mini feeding paperboard size | mm | 300x600/350x600/400x600 |

| 4 | Feeding paper by skip | mm | 1500x2800 |

| 5 | Maxi printing area | mm | 1200x2760 |

| 6 | Over printing precision | mm | ± 0.5/ ± 0.5/ ± 0.3 |

| 7 | Printing plate standard thickness | mm | 7.2 |

| 8 | Printing paperboard thickness | mm | 2-11 |

| 9 | Printing roller axle circular adjust | degree | 360 ° |

| 10 | Printing roller axial adjust | mm | ± 10 |

| 11 | Slotting precision | mm | ± 1 |

| 12 | Mini slotting space | mm | 130 |

| 13 | Maxi slotting depth | mm | 300 |

| 14 | Die cutting precision | mm | ± 1 |

| 15 | Die cutting knife roller axial adjust | mm | ± 10 |

| 16 | Total power(three/four/five/six color) | mm | YKW 51/60/69/78 YKW1/2 85/94/103/114 |

| Note: all above total power parameter does not include the drying configuration | |||

1) The entire machine is designed and produced according to reliable functionality and safety, complying with the European CE standard.

2) The remote computerized maintenance system quickly indicates any source of machine breakdown and figures out a solution. This greatly improves service efficiency and reduces maintenance costs.

3) Every unit features a servo motor drive that eliminates gear driving errors.

4) Each unit has an emergency switch that can shut the equipment down for operator safety.

5) Effectively collects paper dust and prevents it from entering the outside air.

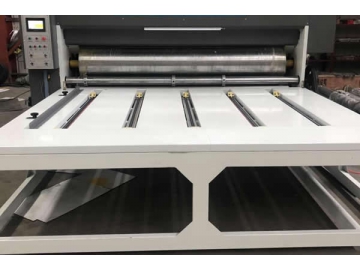

Feeding unit

Feeding unit1) Adopts an American design from Sun company that can feed paper continuously or by partition at high speed.

2) The feeding unit is fitted with an inverter to adjust vacuum air flow and pressure to match the paperboard size.

3) The main motor features a starting protective device. If all units do not lock, the main motor does not start.

4) Single roller feeding with a rubber roller that is designed with a quick change structure.

5) The side baffle adopts a pneumatic patting paperboard.

Printing unit

Printing unit1) The anilox roller is designed with a clutch structure, as it breaks away from the main drive.

2) The anilox roller and doctor blade are designed to prevent unnecessary abrasion and prolong their useful lives.

3) Servo controlled printing phase.

4) Using vacuum transmission,the paperboard feeds steadily, removing the need to install an auxiliary pulling paper cushion.

5) SUN Autmation designed colorful doctor blade results in printing effects that are perfect and clear.

6) Independent servo drive with high precision and efficiency.

Heating unit

Heating unit1) Smooth paperboard delivery via vacuum transmission.

2) Quickly heats paperboard after printing to improve machine speed and printing quality.

3) The heating unit prevents dust from the slotting and die cutting enter into printing unit.

4) Infrared and ultraviolet drying methods available to choose from.

Die cutting unit

Die cutting unit1) Die cutting phase adopts a computerized digital control.

2) The knife mold roller lateral movement adopts an electric adjustment, adjusting range is ±10mm.

3) Rubber roller and knife mold roller gap are electronically adjusted.

4) Knife mold roller is independently servo motor driven.

5) Rubber roller linear speed auto compensation device.

6) Independent servo drive with high precision and efficiency.

SStacking unit

SStacking unit1) Platform rises up and down with safety features to protect the operator.

2) Frequency conversion adjustment of the speed drive.

3) The receiving paper belt adopts vacuum absorption transmission neatly stack the paperboard.

4) Fan and brush work together to clear scraps from the slotting unit and die cutting unit.

Related names:

Cardboard flexo printing machine | Paperboard production equipment | Corrugated fiberboard slotting machine