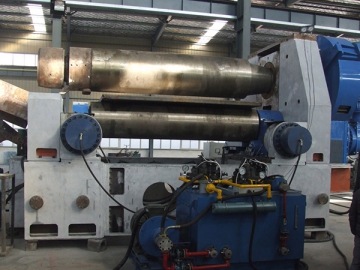

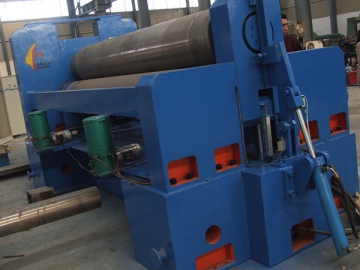

Plate Bending Machine, 3 Roll (Horizontal Movement Type)

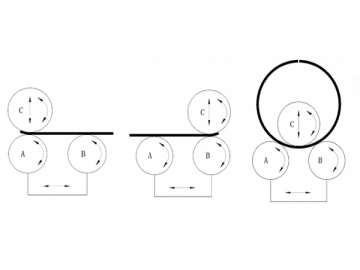

At Juli, we are proud to offer a wide range of 3 roll plate bending machines for rolling many thicknesses and diameters of cylinders. On this page, we are going to introduce to you our W11XNC series 3-roll benders. Their top roll moves up and down on the vertical plane while lower rolls move left and right on the horizontal plane. Horizontal lower roll movement enables the roll bending machine to pre-bend the plate in both side without having to turn it the other way around. Currently, the metal bending machine is an excellent solution for rolling cylindrical, conical, oval, U shape and other shape parts.

Model Selection

| Model | W11XNC-25×1000 |

| Max. rolling thickness | 25mm |

| Max. rolling width | 1000mm |

| Pre-rolling thickness | 20mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter (inner diameter) | Φ700mm |

| Top roll diameter | Φ340mm |

| Lower roll diameter | Φ280mm |

| Lower roll center distance | 380mm (adjustable) |

| Lower roll horizontal movement stroke | ±210mm |

| Synchronous accuracy of top roll and lower roll | ±0.15mm |

| Rolling speed | 4.5m/min |

| Power supply | 380V, 50Hz |

| Motor power of hydraulic system | 15KW |

| Hydraulic system pressure | 20Mpa |

| Straight flange length of pre-rolling plate | ≤2 times plate thickness |

| Dimensions | 4050mm ×2250mm ×1850mm |

| Weight | 11.5T |

| Model | W11XNC-32×2500 |

| Max. rolling thickness | 32mm |

| Max. rolling width | 2500mm |

| Pre-rolling thickness | 26mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter | Φ1000mm, 1.2 times than top roll |

| Top roll diameter | Φ480mm |

| Lower roll diameter | Φ380mm |

| Lower roll center distance | 480mm |

| Lower roll horizontal movement stroke | ±210mm |

| Synchronous accuracy of top roll and lower roll | ±0.15mm |

| Control mode | Japanese imported PLC controller |

| Display mode | LCD display |

| Rolling speed | 4m/min |

| Power supply | 380V 50Hz |

| Motor power of hydraulic system | 22KW |

| Hydraulic system pressure | 16Mpa |

| Model | W11XNC-100×3000 |

| Max. rolling thickness | 100mm |

| Max. rolling width | 3000mm |

| Pre-rolling thickness | 90mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter | Φ2200mm |

| Top roll diameter | Φ850mm |

| Lower roll diameter | Φ680mm |

| Lower roll center distance | 800mm |

| Rolling speed | 3.2m/min |

| Power supply | 380V 50Hz |

| Main electric motor | 90KW |

| Model | W11XNC-100×3200 |

| Max. rolling thickness | 100mm |

| Max. rolling width | 3200mm |

| Pre-rolling thickness | 90mm(Q235), 65mm(Q345) |

| Straight flange length of pre-rolling plate | ≤2 times plate thickness |

| Min. rolling diameter of full loading | Ф2200mm |

| Min. rolling diameter | Ф1100mm |

| Working roll length | 3250mm |

| Top roll diameter | Ф850mmmm |

| Lower roll diameter | Ф680mm |

| Lower roll center distance | 1050mm, 1410mm |

| Rolling speed | 3m/min |

| Top roll lifting speed | 95/115 mm/min |

| Lower roll movement speed | 220/320 mm/min |

| Max. clearance between top roll and lower roll | 200mm |

| Max. lifting stoke of top roll | 340mm |

| Lower roll horizontal movement stroke | ±180mm |

| Main motor power | 90 KW |

| Motor power of hydraulic system | 22 KW |

| Total power | 90 22=112KW |

| Hydraulic system pressure | 20MPa |

| Max. force of top roll | 12500KN |

| Dimensions (L×W×H) | 8700×3900×4100mm |

| Model | W11XNC-120×3200 |

| Max. rolling thickness | 120mm |

| Max. rolling width | 3200mm |

| Pre-rolling thickness | 110mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter | Φ2500mm |

| Top roll diameter | Φ960mm |

| Lower roll diameter | Φ760mm |

| Lower roll center distance | 1050mm |

| Rolling speed | 3m/min |

| Power supply | 380V 50Hz |

| Main electric motor | 132KW |

Features of the Plate Bending Machine

1. Three driven rolls are characterized by non-slip performance, wider rolling range and notable superiority over single drive of top roll or lower rolls.

2. Rolls are made of 42CrMo steel in forging and surface hardening process, ensuring high strength, surface hardness (HB250~280), excellent wear resistance and long life time.

3. Double-row self-aligning roller bearing for top roll comes with large bearing capacity. It can reduce power loss caused by friction and make it quite easy to adjust top roll tilt.

4. Braking devices are designed for rotating rolls so as to ensure correct positioning and make operation safe and reliable.

5. Top roll’s up and down movement and two lower rolls’ horizontal movement are controlled by computer, with automatic leveling function and digital readouts of roll positions, thus ensuring high rolling position and easy operation. Synchronization precision is up to ±0.15mm.

6. Top roll of the sheet metal bender realizes single end tilting and can move vertically at tilt state.

7. Plate feeding alignment device prevents misalignment of cylinder end resulted from misaligned feeding.

8. Two hydraulic cylinders used to drive top roll up and down movement are installed at the bottom of the plate bending machine, ensuring low center of gravity and remarkable stability. To be specific, machine body vibration caused by high center of gravity during plate bending can be avoided. Bending force is exerted on the machine base, whereas the frame only bears the torque generated in bending, thus ensuring high stability. Stability is of great importance for large equipment, especially for those used to bending thick plates.

9. Mobile control console with touch screen offers high convenience to operate and clearly displays rolls' positions.

10. High precision displacement sensor is used for real time monitoring of the three roll's positions.

11. The hydraulic bending machine employs OMRON PLC controller that are featured by strong anti-interference ability, long service life, high shock resistance and stability.

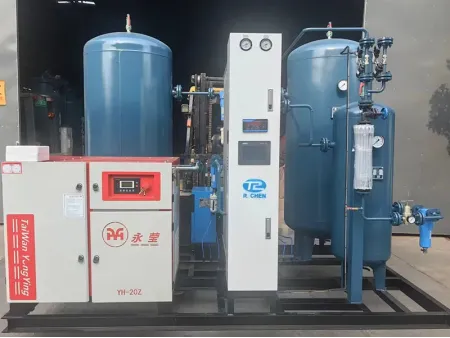

12. Hydraulic system comes with state of the art valve block, reliably sealed tube quick coupler, oil filter, gas filter and safety device.

13. Hydraulic drop end provides quite easy unloading of complete components.

14. Balancing device is equipped on the end of top roll to balance the top roll when the drop end drops.

15. The 3 roll plate bending machine comes with an integrally welded base, ensuring high robustness and ease of installation and handling. Frames and base all feature welded construction and enjoy annealing treatment to eliminate internal stress and improve machine precision. The whole machine features a modular construction, providing an aesthetically pleasing appearance and easy maintenance.

Applicable Industries

Tank truck, chimney, chemical, hydro power, thermal power, shipbuilding, aviation, pressure vessel, pipe, tunnel, bridge, metal structure and machine manufacturing industries.

| Model | Max. rolling thickness (mm) | Max. rolling width (mm) | Pre-rolling thickness (mm) | Min. rolling diameter of full loading (mm) | Top roll diameter (mm) | Lower roll diameter (mm) | Lower rollers center distance (mm) | Rolling speed (m/min) | Main electric motor (kw) | Yield limit of plate (MPa) |

| 12 | 2500 | 8 | 450 | 320 | 220 | 320 | 5 | 11 | 245 | |

| 16 | 2500 | 12 | 450 | 380 | 240 | 320 | 5 | 18.5 | 245 | |

| 20 | 2000 | 16 | 600 | 380 | 240 | 380 | 5 | 18.5 | 245 | |

| 20 | 2500 | 16 | 1000 | 380 | 280 | 380 | 4.5 | 30 | 245 | |

| 25 | 2000 | 20 | 1000 | 380 | 240 | 380 | 4.5 | 30 | 245 | |

| 25 | 4000 | 20 | 1500 | 670 | 450 | 550 | 4 | 45 | 245 | |

| 32 | 2500 | 25 | 1200 | 480 | 380 | 480 | 4 | 30 | 245 | |

| 32 | 3200 | 25 | 1500 | 560 | 380 | 480 | 4 | 45 | 245 | |

| 50 | 3200 | 40 | 2000 | 700 | 500 | 700 | 3.5 | 55 | 245 | |

| 60 | 2500 | 50 | 1500 | 680 | 500 | 700 | 3.5 | 55 | 245 | |

| 70 | 3200 | 60 | 2000 | 800 | 560 | 660 | 3.5 | 75 | 245 | |

| 80 | 4000 | 70 | 2500 | 900 | 650 | 750 | 3 | 75 | 245 | |

| 100 | 3000 | 90 | 2200 | 850 | 680 | 1050 | 3.2 | 90 | 245 | |

| 140 | 4000 | 120 | 5000 | 1150 | 980 | 1150 | 3 | 120 | 245 | |

| Yield limit of plate steel: 245( MPa ) | ||||||||||

| Due to continuous product improvement, actual data may slightly vary. If that happens, please follow the technical parameters in agreement on both sides. Juli reserves the right to revise design, construction and specifications without prior notice. | ||||||||||

Related Names

Hydraulic Bending Machine