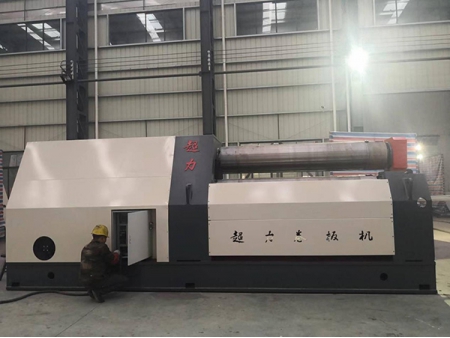

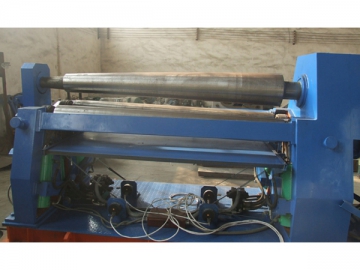

Plate Bending Machine, 3 Roll (Tilting Movement Type)

As a specialist manufacturer of plate bending rolls, Juli offers a wide selection of 3 roll benders for rolling cylindrical, conical and other shape parts. The W11QNC1 series 3 roll plate bending machine is specially designed for rolling conical parts, and can complete feeding, pre-bending and bending at one stroke. In the process of pre-bending, it requires no need to turn the plate the other way around.

Model Selection

| Model | W11QNC1-12×2000 |

| Max. rolling thickness | 10mm |

| Max. rolling width | 2000mm |

| Pre-rolling thickness | 20mm |

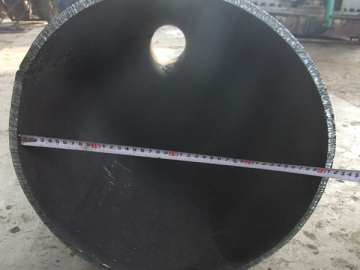

| Roll cone diameter | small end 300mm, big end ≥400mm |

| Yield limit of plate | 304MPa |

| Top roll diameter | small end Φ180mm, big end ≥Φ300mm |

| Lower roll diameter | Φ200mm |

| Rolling speed | 5m/min |

| Side roll lifting speed | 255/330mm/min |

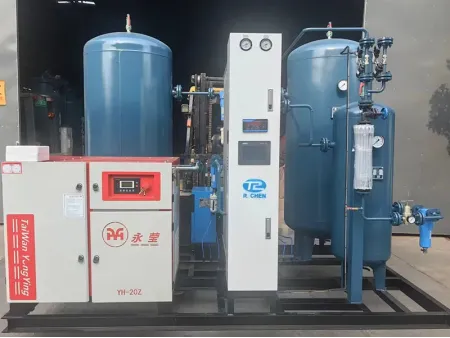

| Motor power of hydraulic system | 15KW |

| Hydraulic system pressure | 20Mpa |

| Main motor power | 7.5kw |

| Motor power of hydraulic system | 3KW |

| Total power | 10.5kw |

| Dimensions | 4930 ×1760 ×1990mm |

| Model | W11QNC1-16×2000 |

| Max. rolling thickness (mm) | 16 |

| Pre-rolling thickness (mm) | 14 |

| Max. rolling width (mm) | 2000 |

| Roll cone diameter (mm ) | Small end 350mm , taper 30° |

| Yield limit of plate ( MPa ) | 245 |

| Top roll diameter (mm) | 300 |

| Lower roll diameter (mm) | 260 |

| Rolling speed (m/min) | 5 |

| Side roll lifting speed ( mm/min) | 255/330 |

| Hydraulic system pressure ( mpa ) | 20 |

| Main motor power ( kw ) | 15 |

| Motor power of hydraulic system ( kw ) | 3 |

| Rolling range | Within 35° |

| Model | W11QNC1-20×2000 |

| Max. rolling thickness (mm) | 20 |

| Pre-rolling thickness (mm) | 16 |

| Max. rolling width (mm) | 2000 |

| Roll cone diameter (mm) | Small end 350mm, taper 30° |

| Yield limit of plate ( MPa ) | 245 |

| Top roll diameter (mm) | 320 |

| Lower roll diameter (mm) | 280 |

| Rolling speed (m/min) | 4.5 |

| Side roll lifting speed (mm/min) | 255/330 |

| Hydraulic system pressure ( mpa ) | 20 |

| Motor power of hydraulic system ( kw ) | 22 |

| Rolling range | Within 35° |

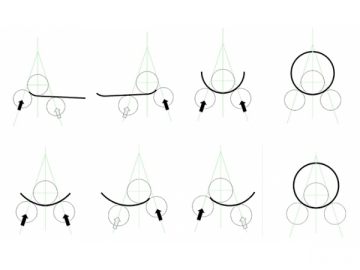

To roll conical parts more easily, the steel plate rolling machine is provided with a cone bending device between the two lower rolls which is driven by hydraulic cylinder to move up and down. It comes with simple structure and compact size, and has no influence on cylindrical parts rolling and unloading.

Features of the Plate Bending Machine

1. The top driven roll is fixed while the two lower rolls can move up and down keeping a certain angle with the horizontal plane. Driven by hydraulic cylinders, they can move synchronously or individually to pre-bend the end of plates.

2. Conical top roll is designed for easier rolling of conical parts at one stroke.

3. The 3-roll plate roll comes with high rolling precision and high speed.

4. It is ideal for forming the conical cylinders with smaller diameter of the small end.

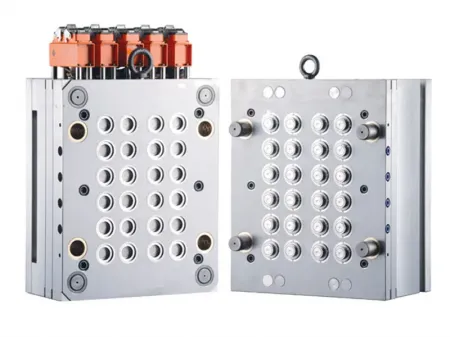

5. High precision displacement sensors are used to ensure positioning accuracy and monitor the positions of three rolls.

6. Control panel adopts OMRON PLC controller and a advanced color touch screen from Taiwan Weilun.

7. The plate bending machine is ideal for in all kinds of industries for rolling conical workpieces.

Juli's Service Assurance

1. Professional after-sales team, on-site installation and commissioning, free operator training;

2. One-year warranty, free maintenance during warranty period, abundant inventory of quick wear parts.

Related Names

Rolling Conical Parts