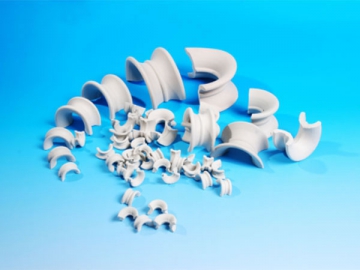

Ceramic Random Packings

Ceramic Raschig Rings / Ceramic Pall Rings | Ceramic Cascade Mini Rings

Ceramic tower packings are known for their acid/alkali resistance and heat resistance, as well as resistance to corrosion caused by inorganic acids, organic acids, and organic solvents, with the exception of hydrofluoric acid. This makes them well suited to usage in high or low temperature conditions, ensuring a wide application range. Applications include drying towers, absorbing towers, cooling towers, washing towers, regenerative towers and desulphurization towers in chemical engineering, metallurgy, coal gas, acid and oxygen production, pharmaceuticals and more.

Ceramic Raschig Rings (CP-100)

Sizes (mm): 3.2, 6, 10, 15, 25, 40, 50, 80, 100 and 150

This is the most basic form of standard packing and simple mass separation, based on a great calculation basis. The surface area is 30% larger than full cylinders or balls, and feature a high mechanical stability.

Ceramic Pall Rings (CP-200)

Sizes (mm): 25, 38, 50, 80

A ceramic pall ring is an open hole, improved cylindrical ring with an identical height and diameters, as well as 3 ligules towards the inside of every stage. The open surface accounts for 30% of the entire wall surface, allowing liquid and gas in the tower to flow freely from the window of the rings. This gives the ceramic pall ring a higher gas and liquid loading, lower pressure drop and a higher performance.

Ceramic Cascade Mini Ring (CP-300)

Sizes (mm): 25, 50, 76

The CP-300 ceramic cascade mini ring is a new hole packing further developed on the basis of the pall ring. Its surface area can be increased by 10-20% more than the pall ring, with a pressure drop reduced by 30-40% and a separating efficiency of varying degrees depending on the specific process improvement.

Ceramic Cross Partition Ring (CP-700)

Sizes (mm) 50, 80, 100, 120, 150

The ceramic cross partition ring has improved on the basis of cylindrical rings, and adds the cross partition. These rings increase the surface and improve the transfer efficiency, ensuring the cylindrical tower packing is systematically stacked in different designs and sizes as an intermediate support between grid and tower packing layers.

Ceramic Saddle (CP-400)

Sizes: 1/2", 3/4", 1", 1.5", 2", 3"

A ceramic saddle is known for its high capacity and excellent liquid distribution. It is also classed as a standard paucity. We offer the ceramic saddles with a glazed construction in order to enhance the capacity and reduce porosity. Their smooth surface ensures a high chemical resistance with a high level of stability.

Ceramic Super Saddle (CP-500)

Sizes: 1", 1.5", 2", 3"

The CP-500 is an improved version of the ceramic saddle, designed for an enhanced natural gas and liquid distribution. The unique scalloped edge is the key to the ceramic saddle’s high performance in terms of a high capacity and rates of mass transfer.

Ceramic Berl Saddle (CP 600)

Sizes: 3/8", 3/4", 1", 1.5", 2"

This features similar properties as the ceramic saddles, but a higher performance based on a larger specific surface and expanded production.