Ceramic Support Ball

Inert Ceramic Ball / Catalyst Support Ball / Alumina Ceramic Ball

As an ISO9001 certified professional factory for production of catalyst support balls, we have the capability to make inert ceramic balls, alumina balls, ceramic pore balls, ceramic cylinders, ceramic refractory balls, and ceramic grinding balls/media, as well as ceramic tower packings (plastic, metal tower packings), honeycomb ceramic RTO/RCO, absorbents, activated alumina, and molecular sieves.

Size range (mm): 3, 6, 8, 10, 13, 19, 25, 38, 50, 76, 100

17%, 23%, 25%, 40% AL2O3 catalyst support media inert ceramic ball

Features

1. The inert ceramic ball features an excellent stability in both chemical and thermal circumstances.

2. These catalyst support balls are resistant to acid, alkali, salt and other organic solvents. They are widely used as a support and covering material in refractors found in oil refineries, and a variety of industries, including chemicals, fertilizers, natural gas, and environmental protection.

3. Each alumina ceramic ball can be used in a temperature ranging from -100 to 100 °C.

Applications (Ceramic Support Ball)

These ceramic support balls are widely used in gas, chemical, metallurgy, fertilizer, coal chemicals, environmental protection, nuclear and other various reactor and device fields featuring a need for a high temperature resistance, high pressure resistance, low water absorption, high strength, and a high chemical and thermal stability. They are corrosion resistant to acids, alkalis organic solvents, and resistant to thermal shock temperature changes.

Applications (Catalyst Support Media/Ball)

The catalyst support media/balls are used in reaction environments below 1000°C. Ceramic/alumina support balls are widely used in covering or support materials for the catalyst in reactors and tower packing in columns/scrubbers in gas/chemical industries, chemical fertilizer, natural gas and environmental protection. They are also used in the following:

1. Raw material inlet

2. Raw materials are distributed using inert balls and are sent to the catalyst area.

3. The secondary raw materials are formed after contact with the catalyst,

4. Secondary raw materials pass through the inert balls and flow into the next process.

| Composition | Value |

| SiO2 | >70% |

| Al2O3 | 17~23% |

| SiO2 Al2O3 | >93% |

| Fe2O3 | < 1% |

| CaO | < 0.5% |

| MgO | < 0.5% |

| K2O Na2O | 2-4% |

| Index | Unit | Value |

| Specific gravity | g/cm3 | 2.3~2.4 |

| Acid Resistance | % | 99.6 |

| Alkali resistance | % | 85 |

| Operation temperature | °C | 982 |

| Water absorption | % | < 2 |

| Hardness | Moh's Scale | 6.5~8 |

| Bulk density | MT/m3 | 1.30~1.35 |

| Spalling resistance | °C | 427 |

| Crush strength | Kg/particle | KN/particle |

| 1/8''(3mm) | >28 | >0.28 |

| 1/4''(6mm) | >55 | >0.54 |

| 3/8''(9mm) | >110 | >1.08 |

| 1/2''(13mm) | >170 | >1.67 |

| 3/4''(19mm) | >430 | >4.21 |

| 1"(25mm) | >635 | >6.22 |

| 1.5"(38mm) | >910 | >8.92 |

| 2"(50mm) | >1000 | >9.8 |

| 3"(75mm) | >1000 | >9.8 |

Our Regular Package: small bags, super bags with pallet, steel drums, cartons

-

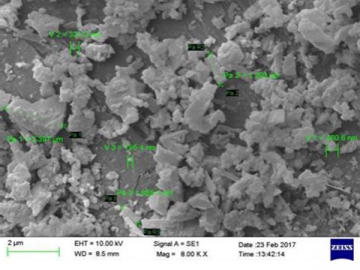

Shape and Size Test

Shape and Size Test  Steel drums

Steel drums Super Sack with Pallet

Super Sack with Pallet

Shape and Size Test

This test verifies the uniform traits of the ball sizes and how that affects flow distribution trends. This factor enhances the appropriate reaction by allowing for a uniform and consistent flow distribution.

Note: We can pack products according to customer requirements, as well as carry out OEM and ODM services.

Due to their outstanding quality and economic prices, our ceramic support ball products are sold worldwide. Many of our long term customers are world-renowned companies, and include China Sinopec, China CNPC, Jordan Petroleum Refinery Co., Ltd, Lantec, CECO, Christy, Air Products and Chemicals, GGI CO., Methanol Chemicals Co, Wide Shine Co., Ltd, STA Products Co., Ltd. Indonesia Petrochemical. With such an extensive list of customers, we guarantee our clients can trust us, and we will do everything to ensure the best possible purchasing experience.