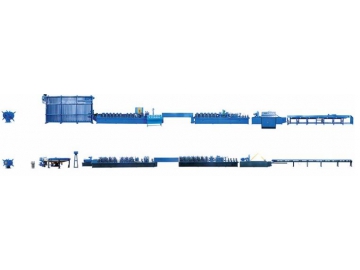

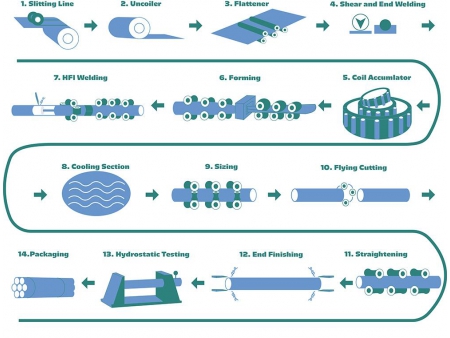

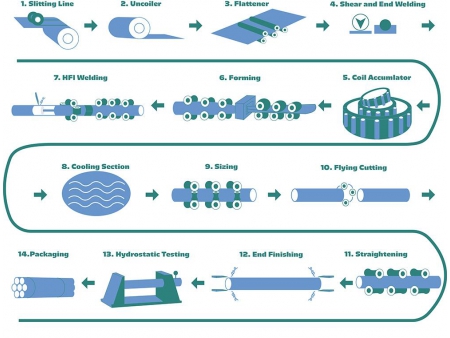

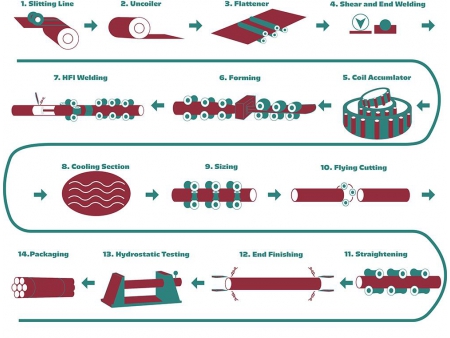

High-Frequency Tube Mill Line

Cold Saw Cut-Off Machine

The cold saw cut-off machine enables the tube profiles to be cut precisely to your required length. This cut-to-length system is equipped with steel structural saw carriage, tube clamping unit, Siemens servo driven linear guide and gear wheel, providing burr-free cutting operation.

There are three control modes, i.e. manual control, simulation control and automatic control. Operators can easily monitor the system and set parameters via human-machine interface.

Horizontal Strip Accumulator

In tube mill operations, strip accumulator plays an essential role in providing continuous strip feeding to the tube mill, eliminating downtime for steel strip processing while enabling the tube mill to run continuously. Our horizontal strip accumulator consists of rotary table, pinch roll motor, main frame and out-feeding unit.

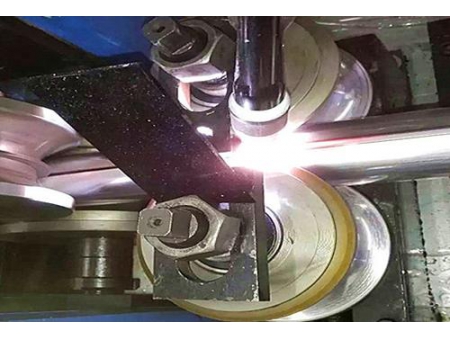

High-Frequency Straight Seam Welded Pipe Mill

Each station of welded pipe mill is consisted of upper roller and lower roller, which are driven by DC motor with the connection of universal shaft and gearbox. Rollers on the shaft are positioned by spacers for centering. The structure of tube mill stand is made of cast iron.

| Model | Outside diameter (mm) | Thickness (mm) | Production speed (m/min) |

| | Ø7.6-16 | 0.3-1.0 | 0-120 |

| | Ø10-25 | 0.3-1.5 | 0-120 |

| | Ø13-38 | 0.6-1.8 | 0-120 |

| | Ø16-50 | 0.7-2.0 | 0-110 |

| | Ø20-63.5 | 0.8-3.0 | 0-90 |

| | Ø25-76 | 1.0-3.2 | 0-80 |

| | Ø32-89 | 1.2-3.75 | 0-80 |

| | Ø35-100 | 1.2-4.5 | 0-75 |

| | Ø50-130 | 2.0-5.0 | 0-60 |

Shear & End Welder

- Composition: pneumatic or hydraulic shear automatic or manual welder (centering of steel strips: manual)

- Function: shear is used to cut strip ends, welder is used for butt welding of steel strip ends

- Construction: strips centering unit, shearing unit, welding unit, moving rack unit, pneumatic or hydraulic system.

Huazhong is committed to the innovation of roll forming machines and helping customers lower their costs and stay ahead in their competitive market.