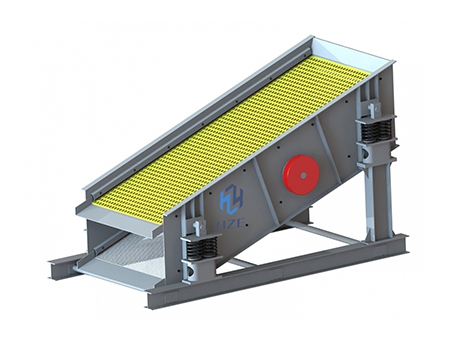

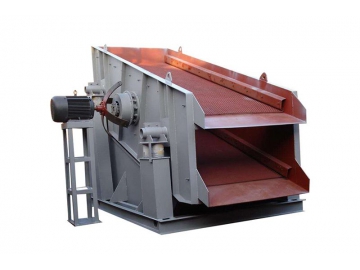

Horizontal Vibrating Screen

Vibrating Screen for Stone Crusher, Crushing Coal Vibrating Screen, Iron Ore Vibrating Screen, Vibrating Screen for Dewatering

DMS series horizontal vibrating screen utilizes the movement of 2 unparalleled eccentric shafts to generate a powerful linear vibrating motion and thus completing the screening process. It is consisted of screen frame, screen, vibrator, shock absorber spring, and transmission part. Our vibrating screen is applicable in sand screening, material grading, dewatering, coal screening, mining, ore screening, and many other uses.

Features of the horizontal vibrating screen

1. With larger vibration force of this screen, materials are transmitted swiftly on the belt, so the production capacity of the screen is larger than others.

2. The superb dewatering performance effectively avoids the materials from blocking, enabling the screening machine to filter particles with small granularity.

3. Ring groove rivet is adopted for the coupling section to realize a high durability of the vibrating screen.

4. Stable running with the belt driving method

Working principle of the vibrating screen

DMH series vibrating screen is comprised of screen frame, screen, vibrator, shock absorber spring, and transmission part, among which the vibrator incorporates 2 eccentric shafts (driving shaft and driven shaft) and gears. The motor drives the driving shaft through the belt and the driven shaft which is engaged with the upper gear of the driving shaft will be motivated. In this way the driving and driven shaft will rotate in an opposite direction simultaneously. The vibration force will be offset downward the 45° direction and become a composition of forces upward the 45° direction. So the trajectory of the vibrating screen is a straight line. Under the composition of forces and the gravity, the materials will be thrown up to jump forward along a line and the screening purpose is met. Dongmeng vibrating screen is distinguished for low energy consumption, high efficiency, simple structure and easy maintenance.

| Model | Dimension (mm) | Number of layers | Processing capacity (t/h) | Vibrating frequency (RPM) | Power (kw) | Weight (t) |

| DMH824D | 900×2400 | 2 | 10-16 | 950 | 5.5 | 1.7 |

| DMH1230D | 1200×3000 | 2 | 10-90 | 950 | 11 | 2.6 |

| DMH1230T | 1200×3000 | 3 | 30-90 | 950 | 11 | 3 |

| DMH1536D | 1500×3600 | 2 | 50-190 | 950 | 15 | 3.4 |

| DMH1536T | 1500×3600 | 3 | 50-200 | 950 | 18.5 | 4.7 |

| DMH1848D | 1800×4800 | 2 | 50-280 | 950 | 30 | 6.9 |

| DMH1848XT | 1800×4800 | 3 | 50-300 | 950 | 37 | 8.1 |

| DMH2160XD | 2100×6000 | 2 | 100-330 | 950 | 37 | 8.9 |

| DMH2160XT | 2100×6000 | 3 | 100-380 | 950 | 45 | 11.5 |

| DMH2460XD | 2400×6000 | 2 | 100-380 | 900 | 45 | 10.6 |

| DMH2460XT | 2400×6000 | 3 | 160-450 | 900 | 55 | 12.4 |