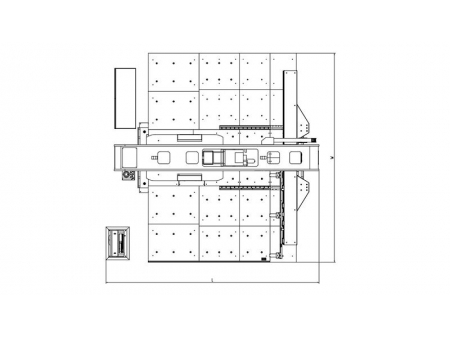

CNC Servo Turret Punch Press

DAS Series

DAS Series

DAS series CNC servo turret punch press adopts direct drive structure consisting of a servo motor, crankshaft and connecting rod, which is mature and reliable. It effectively eliminates mechanical clearance, resulting in high transmission precision, low noise, long lifespan, and minimal maintenance requirements. The use of closed-loop servo motors enhances the forming effect. With energy-saving design, it can efficiently recover braking energy generated during actual operation, effectively reducing the operating costs.

- Sheet metal processing

- Electronic enclosure manufacturing process

- Automotive parts manufacturing

- Processing of aluminum curtain walls

- Enclosure/Cabinet bending processing

- Kitchenware bending

- Engineering machinery component processing

- Elevator component processing

- Processing of small home appliances (including lighting fixtures)

(cutting thickness: 6 to 16mm)

| Model | ||||

| Punching capacity (kN) | 300 | 300 | 300 | |

| Punching driver | Servo drive | |||

| Processing range | Max. thickness (mm) | 6.35 | 6.35 | 6.35 |

| Max. sheet size (mm) | Φ88.9 | Φ88.9 | Φ88.9 | |

| Max. sheet size (mm) | 1250x5000 | 1500x5000 | 2000x5000 | |

| X/Y stroke (mm) | 1250x2500 | 1500x2500 | 2000x2500 | |

| Number of station | 32(2AI) | 32(2AI) | 32(2AI) | |

| Max. moving speed (m/min) | 100 | 100 | 100 | |

| Turret speed (rpm) | 30 | 30 | 30 | |

| Punch frequency (hpm) | 1500 | 1500 | 1500 | |

| Number of control axis | 5 (X/Y/A/C/P) | 5 (X/Y/A/C/P) | 5 (X/Y/A/C/P) | |

| CNC system | Fanuc 0i-PF | |||

| Punching precision (mm) | ±0.10 | ±0.10 | ±0.10 | |

| Comprehensive power (kW) | 6.5 | 6.5 | 6.5 | |

| Repetition accuracy (mm) | ±0.03 | ±0.03 | ±0.03 | |

| Dimensions (L*W*H) (mm) | 4800×5120×2330 | 5300×5120×2330 | 6300×5120×2330 | |

| Weight (kg) | 14000 | 15500 | 19000 | |

- Servo main drive

- Servo control ensures high speed and mute punching

- O-shaped frame structure

- Water cooler and air conditioner

- Gripper

- Brush table with inserted roller balls

- Auto-index (station)

- Turret drive

- Tooling

Standard thick turret long tooling ensures good guiding performance, long service life and high precision.

- Feeding mechanism

The feeding mechanism adopts Japanese THK precision ground ball screw, large diameter linear guide and servo direct drive, ensuring high positioning accuracy, fast running speed and low noise.

- Thick turret with sleeve

- Hardened tooling sleeve

The main body of the turret sleeve undergoes fine grinding after hardening, offering better wear resistance and easy replacement, thus effectively improving the service life of the tooling and the turret.

- Repositioning and sheet metal deformation detection device

- Self-lubricating system

- Japan FANUC Oi-PF CNC system (standard)

- Israel CNCKAD programming software

- Germany SIEMENS 840Dsl CNC system

- Multi tooling function

- Vacuum waste suction installation

- Anti-dropping clamp device

- Automatic clamping device