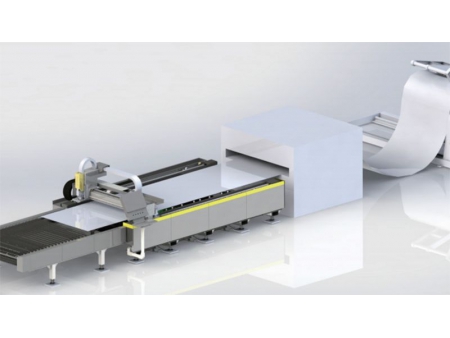

Coil-Fed Laser Blanking Line

Super S-F Series

Super S-F Series

Super S-F series Coil-fed laser blanking machine, innovatively developed by DERATECH, is an automated flexible manufacturing line that integrates functions of uncoiling, feeding, cutting, and discharging. It has broad applications in industries that require continuous production of various metal sheet products, such as metal doors and windows, HVAC equipment, chassis cabinets, shelves, and filing cabinets. This production line revolutionizes traditional processing methods by transforming single-cutting processes into one-stop processing lines. This facilitates continuous and automated production, significantly reducing labor cost while improving equipment utilization and material efficiency, creating more value for users.

- 4-in-1 Function

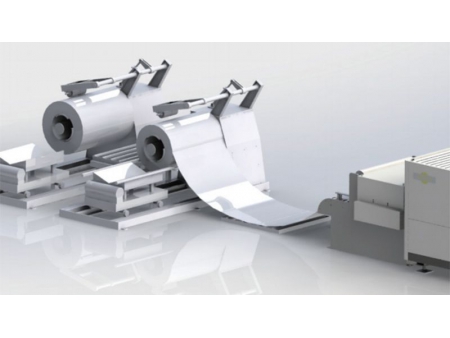

This laser blanking machine has four functions of uncoiling, feeding, cutting and discharging, enabling continuous and automated production.

- Structural innovation, economical and practical

The hydraulic leveling machine does not require excavation of foundation pits, reducing initial investment and facilitating equipment relocation. The worktable with structure achieves automatic discharge.

- Flexible Processing

Uncoiling, clamping, and feeding length can be freely set, allowing for flexible switching between different part shapes and rapid response to changes in production needs.

- Optional For More Functions

Optional robotic unscrambler for intelligent sorting and palletizing, saving labor. Optional winding / laminating / waste collection functions.