Solar Glass Rolling Machine

Rolled Glass Production Line, Hot End

Glass rolling machine for continuous production of photovoltaic (PV) glass

The solar glass rolling machine works as the main forming unit in a rolled glass production line. Positioned between the melting furnace and the annealing lehr, it works together with the lift-out roller to shape the glass ribbon while it is still hot and flexible. Through this forming process, the glass processing line can reliably produce ultra-thin glass sheets with thicknesses down to 1.1 mm, while keeping stable mass production at around 1.4 mm thickness. It can also handle panels up to 4000 mm wide, which are widely used for manufacturing large solar modules. Since the glass rolling system works with high precision, the glass processing line reaches yield rates above 85%, ensuring consistent production of PV glass with excellent light transmission.

| Power | 32.4kW |

| Working pressure | 0.6MPa |

| Working accuracy | ±0.02mm |

| Production capacity | 600t/d (max.) |

| Working pressure | 15t |

| Glass thickness | 1.2-4mm |

| Glass width | 2.8-5.4m |

| Top/bottom roller diameter | 240-450mm (customizable) |

| Glass rolling speed | 57.85-578.5m/h (customizable) |

- Flat-plate rolling machine

- Self-weight rolling machine

- Lift-out roller

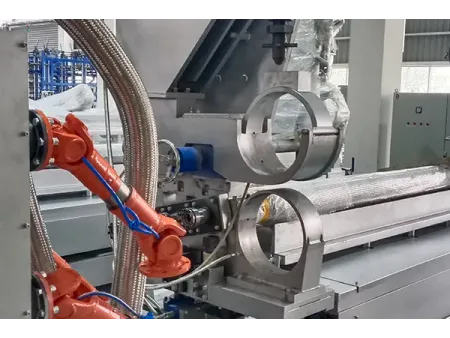

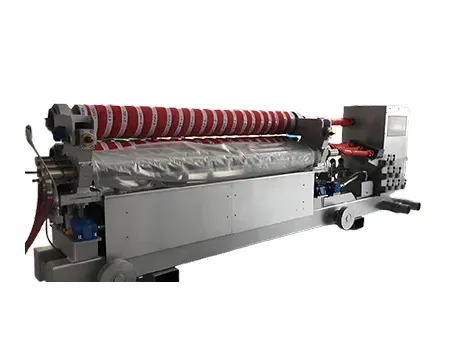

- Main Rolling Machine Unit

The main part of the rolling machine includes the rollers that shape the glass, support rollers, the drive system, cooling units, and an air-cushion system. It also has adjustment controls on all sides, so operators can set the position of the rollers and keep the glass sheet even and stable while it’s being formed. - Lift-Out Roller

The lift-out roller has a sturdy steel frame, with cooling water running inside the tubes to keep it from bending under high heat. This design helps the glass stay stable as it moves through the forming stage. - Pressure Rods

Two pressure rods are installed on the upper part of the rolling machine, one on the drive side and the other on the non-drive side. Each rod can push with up to 20 tons of force, giving the machine the strength to keep the glass ribbon flat and under control while it’s being shaped.

| Customer | Setup | Furnace Capacity | Units Installed | Ribbon Width | Start of Operation | Thickness Range |

| Almaden | One furnace with two glass production lines | 320 t/d | 4 units | 2570 mm | April 2018 | 1.6-4 mm |

| Egypt Float Glass | One furnace with one glass production line | 120 t/d | 2 units | 2500 mm | March 2021 | 2-4 mm |

| India Adani | One furnace with four glass production lines | 650 t/d | 8 units | 3150 mm | February 2022 | 1.6-4 mm |

| Turkey | One furnace with two l glass production lines | 320 t/d | 4 units | 3150 mm | March 2022 | 1.6-4 mm |

| SYP | One furnace with two glass production lines | 320 t/d | 4 units | 2850 mm | July 2021 | 1.6-4 mm |