Frozen Meat Flaker / Frozen Block Flaker

The frozen meat flaker is constructed entirely from SUS304 stainless steel, with blades made from high-quality alloy steel. By replacing blades of different heights, the thickness of slices or flakes can be adjusted, and the processing capacity can reach 3 tons per hour.

An integrated raw-meat operating platform makes operation more convenient and labor-saving. The chute and raw meat operate in separate zones, preventing contamination of the raw materials. The cutter drum features a fully enclosed end-mounted structure, ensuring no contamination of the meat during processing.

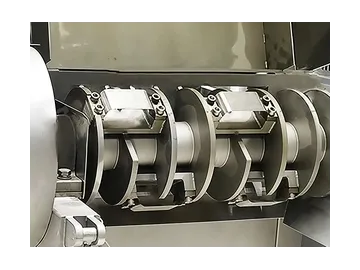

The drum is equipped with six blades, all made of premium alloy steel. The drum is driven by a motor and rotates at 335 rpm.

The machine is designed to efficiently flake frozen meat at temperatures up to –18°C.

It can handle frozen blocks within 700 × 520 × 200 mm (L×W×H).

Three blade heights are available; switching between blade heights allows users to adjust slice or flake thickness.

The electrical system has a protection rating of no less than IP55 and an insulation class of Class B.

The machine is equipped with an operating platform, making operation convenient and labor-saving.

It includes a cleaning function and an automatic feeding function, and can be paired with a standard meat trolley.

Key Parameters

| Model | HK-5230 |

| Power | 11 kW |

| Channel width | 520 mm |

| Slice/flake thickness | 6, 20, 35 mm |

| Cylinder stroke | 520 / 700 mm |

| Max processing capacity | 3 T/h |

| Drum max rotation diameter | 340 mm |

| Drum min rotation diameter | 293 mm |

| Blade drum speed | 335 rpm |

| Feeding method | Pneumatic forced feeding |

| Weight | 760 kg |

| Dimensions | 2420 × 1060 × 1150 mm |

Features

- Sharp blade assembly

Circular blade structure enables efficient flaking of frozen meat. Modular design allows easy removal and cleaning.

- Function control buttons

Multiple control modes allow the feeding method to be switched automatically.