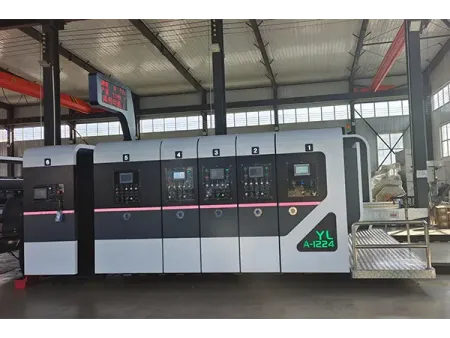

Printer Slotter Rotary Die Cutter with Lead Edge Feeder, CZYL-A

Corrugated Cardboard Converting Machines

The Printer Slotter Rotary Die Cutter with Lead Edge Feeder is designed to handle multiple processes in a single pass, including four-color printing, slitting, creasing, trimming, slotting, and rotary die cutting. It features a front-edge positioning automatic feeder with adjustable air volume for smooth and accurate sheet delivery, while the main motor uses frequency conversion control for stable and efficient operation. The entire machine is managed through a PLC system with a color display screen, offering convenient, fast, and flexible multi-functional control. Operators can store unlimited orders with one-click changeover for quick transitions between jobs. Versatile and efficient, this printer slotter is suitable for 3-layer, 5-layer, 7-layer, and E-flute corrugated board production.

- High-Precision Feeding System

Advanced vacuum-assisted front-edge feeding ensures stable operation, easy handling, and accurate sheet feeding. - Smart Touch Screen Control

7-inch full-color display with capacity for 200 preset orders, order queries, zero-point settings, automatic/manual phase adjustments, parameter management, ink distribution control, and real-time production data display. - Durable Transmission Rollers

Made of high-quality steel with hard chrome plating and precision grinding, ensuring long service life and consistent performance. - Reliable Gear Mechanism

Premium alloy steel drive gears, heat-treated and ground for precision, with high-accuracy self-locking worm gear clearance adjustment supported by a three-rod disc handle for quick operation. - Adjustable Slotting Unit

Electrically controlled system for precise positioning of knife axis, vertical alignment, and box height dimensions. - Efficient Die-Cutting Compensation

Cam-driven soft roller with 40 mm lateral movement ensures uniform wear of the rubber pad, increasing utilization and reducing operating costs.

| Model | ||||||

| Max. speed (sheets/min) | 300 | 260 | 250 | 200 | 180 | 150 |

| Paper feeding accuracy (mm) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Min. sheet size (mm) | 250×500 | 250×500 | 320×600 | 320×600 | 380×600 | 380×600 |

| Max. sheet size (mm) | 850×2000 | 850×2200 | 1150×2400 | 1150×2800 | 1350×2600 | 1550×2800 |

| Skip feeding sheet size (mm) | 1200×2000 | 1200×2200 | 1400×2400 | 1400×2800 | 1600×2600 | 1800×2800 |

| Max. printing area (mm) | 820×2000 | 820×2200 | 1150×2400 | 1150×2800 | 1400×2600 | 1550×2800 |

| Printing accuracy (mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Printing plate thickness (mm) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| Min. slotting size (L×W×H) (mm) | 220×60×70 | 220×60×70 | 250×60×80 | 250×60×80 | 250×60×80 | 250×60×80 |

| Min. die cutting size (L×W×H) (mm) | 170×80×80 | 170×80×80 | 180×80×80 | 180×80×80 | 180×80×80 | 180×80×80 |

| Max. slotting depth (mm) | 230 | 230 | 310 | 310 | 370 | 410 |

| Additional knifes can be added to increase slotting depth | ||||||

| Slotting accuracy (mm) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Max. die cutting size (mm) | 900×2000 | 900×2200 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 |

| Die cutting accuracy (mm) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

- Lead Edge Feeding Unit

- Printing Unit

- Rotary Die Cutter Unit with Six Axes and Nine Servos

- Slotting Unit

- Clear Waste Stacking Machine (Optional)