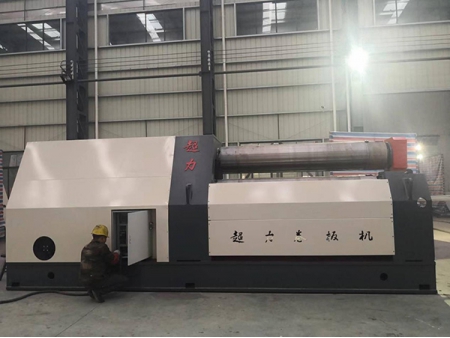

Plate Bending Machine, 3 Roll (Arc Movement Type)

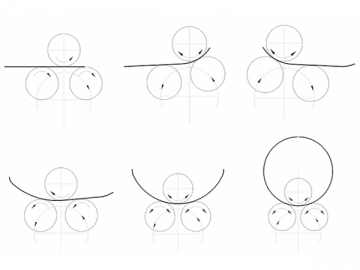

The W11HNC series 3 roll plate bending machine are designed for rolling various thicknesses and diameters of cylindrical, conical, oval, U shape and other shape parts. They come with three drive rolls. The top roll does not change its position while lower rolls move up and down in an arc way. Two lower rolls can move synchronously or separately. This series sheet metal roll holds a capability to pre-bend the plate and complete pre-bending and forming at one stroke without having to turn it the other way around.

Model Selection

| Max. rolling thickness | 4mm |

| Max. rolling width | 3000mm |

| Pre-rolling thickness | 3mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter of full loading | Φ400mm |

| Top roll diameter | Φ240mm |

| Lower roll diameter | Φ240mm |

| Rolling speed | 4m/min |

| Motor power | 7.5KW |

| Hydraulic system pressure | 16Mpa |

| Max. rolling thickness | 25mm |

| Max. rolling width | 2000mm |

| Pre-rolling thickness | 20mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter of full loading | Φ1000mm |

| Top roll diameter | Φ330mm |

| Lower roll diameter | Φ330mm |

| Rolling speed | 4.5m/min |

| Motor power of hydraulic system | 18.5KW |

| Hydraulic system pressure | 20Mpa |

| Dimensions | 4130mm ×1960mm ×1750mm |

Features of the Plate Bending Machine

1. It is a hydraulic type 3 roll bending machine, with all movements driven by hydraulic system and controlled by PLC control console.

2. The top roll is immobilized while the two lower rolls swing up and down around a fixed center. Two lower rolls can move separately or synchronously.

3. All three rolls can be driven individually, ensuring excellence in bending steel plates of any thickness.

4. Three rolls can stay so close to each other that the plate bender is best choice for rolling small diameter cylinder.

6. Made of 42CrMo steel, via forging and surface quenching and tempering process, the rolls come with excellent strength, wear resistance and high longevity, and they are suitable for high load works.

7. The plate bending machine is designed with a mobile control panel for easy operation. Touch screen on the panel can clearly show the position of rolls.

8. High precision displacement sensor ensures real time monitoring for lower rolls’ positions and thereby ensuring position accuracy.

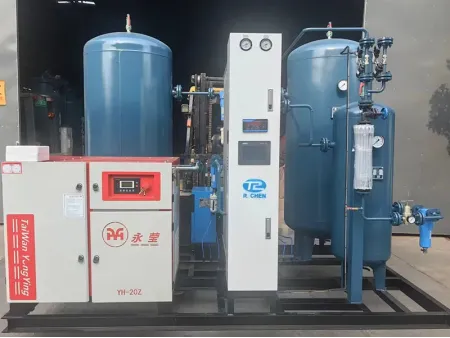

9. Main valve blocks in the hydraulic system are from Taiwan NORTHMAN. They feature cast flow circuit, large flow, small resistance, low pressure loss, and low heat, making performance of the plate rolling machine more reliable.

10. Hydraulic tubing employs quick connectors in cone seals which provide reliable radial seal so that oil leakage of hydraulic system can not happen.

11. The hydraulic plate roll’s hydraulic system is provided with oil filter for system cleaning as well as air filter for normal air in and out of oil tank and water evaporation. The system comes with double-way safety protection device to maximize safety in use.

12. The 3 roll plate bending machine’s drop end (unloading device) is driven by a hydraulic cylinder to realize automatic drop and erection, thus ensuring ease of workpiece unloading. Due to an interlocking device, other actions of the machine will stand by when the hydraulic drop end turns over, and only after the drop end erects can the machine runs again. This ensures high safety.

13. It is equipped with a balancing device at the end of top roll to balance the top roll when the drop end turns over. As the top roll can keep balance because of the device, cylindrical parts are easy to be unloaded.

14. The 3 roll plate bending machine comes with an integrally welded base. Both frames and base feature welded construction and enjoy annealing treatment to eliminate internal stress and improve machine precision. The whole machine boasts a modular construction, providing an aesthetically pleasing appearance and ease of maintenance.

Applicable Industries

The forging machine is suitable for use in various industries including Tank truck, chimney, chemical, hydro power, thermal power, shipbuilding, aviation, pressure vessel, pipe, tunnel, bridge, metal structure, machine manufacturing, etc.

| Model | W11H- W11HNC- | |||||||||||

| 6× 2000 | 8× 2000 | 12× 2000 | 16× 2000 | 20× 2000 | 25× 2000 | 25× 2000 | 32× 2000 | 35× 2500 | 50× 2500 | 60× 2500 | 75× 2500 | |

| 12× 2500 | 16× 2500 | 20× 2500 | 20× 3200 | 25× 3200 | 32× 3200 | 40× 3200 | 50× 3200 | 60× 3200 | ||||

| 4× 2500 | 6× 2500 | 8× 2500 | 8× 3200 | 12× 3200 | 16× 3200 | 16× 4000 | 20× 4000 | 25× 4000 | 32× 4000 | 40× 4000 | 50× 4000 | |

| Pre-rolling thickness (mm) | 4 | 5 | 8 | 12 | 14 | 20 | 20 | 25 | 250 | 42 | 50 | 60 |

| 8 | 12 | 14 | 14 | 20 | 25 | 32 | 40 | 50 | ||||

| 2 | 4 | 5 | 6 | 8 | 12 | 12 | 14 | 20 | 25 | 32 | 40 | |

| Yield limit of plate steel (MPa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 |

| Min. rolling diameter of full loading (mm) | 500 | 550 | 600 | 700 | 800 | 1100 | 800 | 1300 | 1500 | 1700 | 1900 | 2000 |

| Rolling speed (m/min) | 5.2 | 5 | 5 | 4.5 | 5 | 4 | 5 | 4 | 4 | 3 | 2.5 | 2 |

| Main electric motor (KW) | 5.5 | 5.5 | 5.5 | 7.5 | 18.5 | 18.5 | 18.5 | 22 | 30 | 55 | 55 | 75 |

| Dimension (mm) | 3.21× 1.17× 1.31 | 3.21× 1.17× 1.31 | 4.15× 1.32× 1.49 | 3.92× 1.62× 1.64 | 4.38× 1.36× 1.49 | 4.13× 1.96× 1.75 | 4.63× 1.96× 1.75 | 4.6× 2.42× 2.51 | 5.7× 2.85× 2.97 | 6.35× 2.66× 3.02 | 6.4× 3.2× 3.5 | 6.7× 3.3× 3.6 |

| 4.42× 1.62× 1.64 | 4.88× 1.36× 1.49 | 4.63× 1.96× 1.75 | 5.33× 1.96× 1.75 | 5.3× 2.42× 2.51 | 6.4× 2.9× 3 | 7.05× 2.66× 3.02 | 7.1× 3.2× 3.5 | 7.4× 3.3× 3.6 | ||||

| 3.71× 1.17× 1.31 | 3.71× 1.17× 1.31 | 4.65× 1.32× 1.49 | 5.12× 1.62× 1.64 | 5.58× 1.36× 1.49 | 5.33× 1.96× 1.75 | 6.13× 1.96× 1.75 | 6.1× 2.42× 2.51 | 7.2× 2.9× 3 | 7.85× 2.66× 3.02 | 7.9× 3.2× 3.5 | 8.2× 3.3× 3.6 | |

Due to continuous product improvement, actual data may slightly vary. If that happens, please follow the technical parameters in agreement on both sides. Juli reserves the right to revise design, construction and specifications without prior notice.

Related Names

Cone Rolling Machine | Cone Forming Rolling Machine