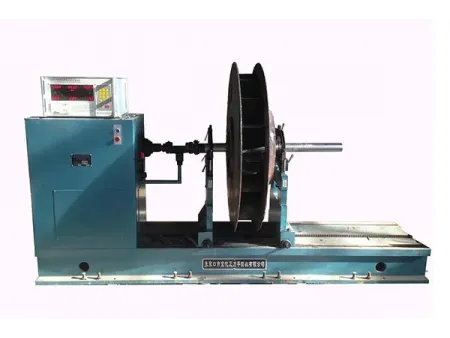

Fan Impeller Balancing Machine

Request a Quote

YFW-300/YFW-500

Hard-bearing balancing machine for dynamic balancing of fan impellers and blowers

The YFW-300 and YFW-500 are hard-bearing balancing machines designed for manufacturers of fans, motors, crushers, drums, textile machinery, and medium to small agricultural equipment. With their safe hard-bearing structure, easy calibration, and simple operation, they deliver reliable and efficient balancing performance.

A key advantage of these fan impeller balancing machines is their ability to handle workpieces with a rotational diameter of up to 1200 mm, making them suitable for the dynamic balancing of large fan impellers. They are also well-suited for other high-speed rotating parts such as flywheels, pulleys, cutter discs, and crankshafts.

Specifications

| Workpiece weight | 15-300kg | 20-500kg | |||

| Max. workpiece diameter | Ø1400mm | Ø1600mm | |||

| Journal diameter of workpiece | Standard roller carriage | Ø10-Ø90mm | Standard roller carriage | Ø10-Ø90mm | |

| Optional roller carriage (as per customer request) | Ø90-Ø180mm | Optional roller carriage (as per customer request) | Ø90-Ø180mm | ||

| Distance between two bearing supports | 1500/2100mm (or based on negotiation) | 1500/2100mm (or based on negotiation) | |||

| Min. achievable residual unbalance (eMar) | 1g.mm/kg | 1g.mm/kg | |||

| Unbalance reduction ratio (URR) | ≥90% | ||||

| Balancing speed (stepless speed control) | High speed (specimen ≤160kg) | 520/1040 r/min | High speed (specimen ≤160kg) | 520/1040 r/min | |

| Low speed | 260/520 r/min | Low speed | 260/520 r/min | ||

Features

- Configurable with either the ZL-220 embedded electrical measurement unit or the advanced ZL-2 dynamic balancing system.

- The ZL-2 system integrates the latest USB data acquisition card with an industrial PC or integrated computer, offering high stability and excellent anti-interference capability.

- Software developed with NI LabVIEW virtual instrument technology provides an intuitive and user-friendly interface, adaptable to various user levels and testing environments.

- Flexible software architecture allows for extensive function expansion and customization based on user-specific requirements.

- Equipped with an advanced photoelectric coupler for reference signal input and a concealed piezoelectric sensor for vibration signal detection, ensuring accurate and consistent results.