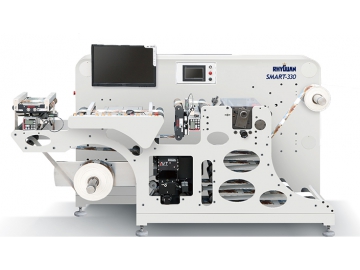

Label Converting Machine (Cold Stamping)

The TOP-330 PLUS label converting machine is a label finishing system that includes a flexographic printing system (cold stamping, UV coating, super varnishing, and dot varnishing), lamination, a rotary screen printing system, a semi-rotary die cutting system, sheeting and collection, and rewinding. This cold stamping label machine features a servo-driven system, user-friendly design, high accuracy, and efficiency.

1. Digital Inkjet Platform: Optional printing unit with single or multiple printing head positions.

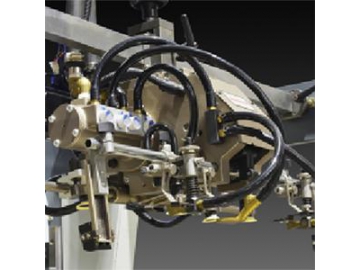

2. UV Flexographic Press Unit: automatic re-register and servo driven system, cold stamping, laminating,flexographic UV coating and super varnishing.

3. Double Shafts Laminator: Laminator with waste removal function is able to accomplish cold stamping and super varnishing in flexographic printing unit.

4. Hot Lamination System: Heated roller with a large diameter for unwinding and laminating, high speed, reduces wasted material thanks to an automatically controlled temperature.

5. Sheeting Unit: Servo-motor driven, precise and efficient.

6. Slitting System: Advanced precision control with shear knife and crash knife.

| Max Speed | 300RPM |

| Register Accuracy | ±0.15mm |

| Accuracy of Cutting | ±0.15mm |

| Max Printing Width | 290mm |

| Printing Girth | 55T-1 6 0T |

| Max Print Area | 508 mm ×320mm (L×W) (160teeth print cylinder) |

| Max Die Cutting Area | 350mm ×320mm (L×W) 9mag. Cylinder in 120 teeth) |

| Paper Width | 80mm ---330mm |

| Max Unwinding Dia | φ700mm (about 2000Meters) |

| Max Rewinding Dia | φ700mm (about 2000Meters) |

| Magnetic Cylinder | 120Teeth 1/8 (Standard) |

| Length of Die Cutting | 50mm ~330mm |

| MOTOR Power | 8 KW |

| UV Lamp Power | 4.8KW |

| Overall Diameter ( L×W×H ) | 3600mm ×1200mm ×1500mm |

| Weight | 3000KG |

Unwinder--Web guider--Flexo system (UV coating and printing and cold foil)----Die cutting (semi-rotary and rotary) ---Rewinder

A: Unwinding

B: Web Guider

C: 120teeth/381mm magnetic cylinder (15inch cylinder)

D: Servo motors (Panasonic imported from Japan)

E: HMI touch screen operating system (Schneider PLC)

F: Flexographic printing system with re-register and foil laminator

G: UV system in 220W/CM