Pre-painted Steel Coil

Coated steel coil/ Pre-painted sheet/ Pre-painted sheet metal

Pre-painted steel coil is made through the coating of galvanized steel coil or galvalume steel coil. After a particular surface treatment, cold rolled steel coil, galvanized steel coil or aluminum zinc silicon alloy coated steel coil will be coated with paint or organic film with certain thickness and then turned into pre-painted steel coil after a solidification and formation process. The coated layer protects the steel coil from being corroded by external factors. Studies have shown that the coated layer increases service life of the steel coil by 50 percent. The pre-painted steel coil is suitable for many areas such as construction of roofs or external walls due to its strength and flexibility. The product is available in various colors so that it can be used for decorative purposes.

Technical Parameters

Standards: JIS G3312/national standard/enterprise standard

Grade: SGCC, SGCH, COMMERICAL QLTY

Thickness:0.15-1.2mm

Width: 750-1250mm

Color: customized

Rolled weight:3-5MT

Surface treatment: double-coating; single drying; double-coating, double-drying; single coating, single drying.

Country of origin: China

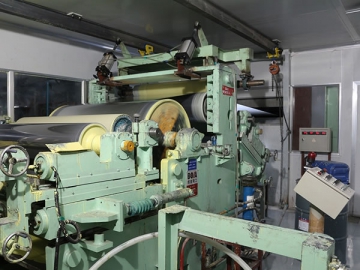

Pre-Painting Line

At present, we have two fully automatic pre-painting lines. For each line, the overall length is about 190m and the designed annual output is 100,000 tons. Suitable raw materials include SPCC or SPCD galvanized steel coil and galvalume steel coil.

Pre-Painting Line: Equipped with an independent hydraulic power unit, the recoiling machine is driven by an electro-hydraulic servo control system. Either a neat single layer rim or multi-layer rim can be achieved if needed. The steel roll rim is strictly controlled within 3mm.

Steel Coil Selection: A roll coater is used for the coating of the steel coil and the coating thickness can be chosen from 0.02 to 0.03mm.

Steel Coil Pre-Painting: To facilitate the control of operating parameters and technical parameters, an interactive touch screen is adopted for the decoiling process, rolling process and pre-painting.

The organic pre-painted layer protects the steel coil from being corroded by external factor. The pre-painted steel coil is able to withstand corrosion for 10 to 15 years. Due to restrictions imposed by raw material and production costs, the minimum order quantity is 50 tons.

Precautions

1. The product should be kept in a well-ventilated dry room, not in the open air since it is difficult to control outdoor temperature differences. Large temperature differences could easily cause moisture condensation to damage the coil.

2. The ground of the storage area should be as flat as possible and hard objects should be also removed. The ground should have a large bearing capacity.

3. Generally, stacking storage should be avoided to prevent damage. In circumstances where stacking storage is applied for some reasons, the number of stacking layers should be strictly controlled and steel coil with heavy weight and large dimensions should be placed at the bottom.

4. Protect the coils from moisture.

5. We do not recommend storage of large quantities of the steel coil in environment rich in sulfur dioxide, and steel coil which has already been exposed to such an environment, should be moved as soon as possible.