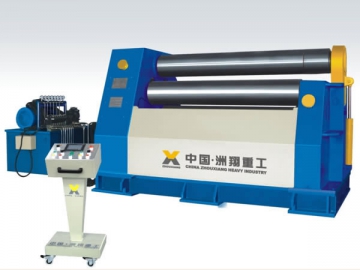

Horizontal 3-Roller Rolling Machine

The horizontal 3-roller rolling machine is controlled by microcomputer. It has digital display function. With the features of simple operation but reasonable structure, high working efficiency and reliability, it is often used to roll the steel plate with the thickness of medium and large size.

The horizontal 3-roller rolling machine can achieve pre-bending and rolling for plate end through upper roller vertical lifting and lower roller horizontal moving with feeding the steel plate only one time. All the three rollers are driving rollers, which allow for no skidding when rolling the thin plate. Meanwhile, the operation range for rolling steel plate is enlarged. Thanks to the braking device for rotating movement of the three rollers, the position of work piece can be located precisely and the safety for operation is assured when doing the rolling process. The one end of the upper roller can be tilted. At the state of tilting, both two ends of the upper roller can achieve rising up and descending simultaneously, which facilitates rolling the work piece into cone-shaped steel. The main drive of the upper roller is achieved by multi-motor confluence, which features compacted structure and decreases the occupied area of equipment.

Technical Parameters| Model | Max. Thickness of Steel Plate for Rolling (mm) | Max. Thickness of Steel Plate for Pre-bending (mm) | Max. Width of Steel Plate for Rolling (mm) | Yield Limit of Steel Plate (Mpa) | Min. Rolling Diameter with Full Load (mm) | Diameter of Upper Roller (mm) | Diameter of Lower Roller (mm) | Center Distance of Lower Rollers (mm) | Rolling Speed (m/min) | Power of Main Motor (kw) |

| W11XNC-60×2500 | 60 | 50 | 2500 | 245 | 1800 | 640 | 520 | 650 | 3.5 | 2×22 |

| W11XNC-60×3200 | 60 | 50 | 3200 | 245 | 2000 | 700 | 560 | 700 | 3.5 | 2×22 |

| W11XNC-60×4000 | 60 | 50 | 4000 | 245 | 2500 | 760 | 600 | 850 | 3 | 2×30 |

| W11XNC-70×2500 | 70 | 60 | 2500 | 245 | 2000 | 700 | 560 | 700 | 3 | 2×30 |

| W11XNC-70×3200 | 70 | 60 | 3200 | 245 | 2000 | 720 | 600 | 900 | 3 | 2×30 |

| W11XNC-70×4000 | 70 | 60 | 4000 | 245 | 2500 | 820 | 630 | 900 | 3 | 2×30 |

| W11XNC-80×3000 | 80 | 70 | 3000 | 245 | 2000 | 770 | 600 | 900 | 3 | 2×30 |

| W11XNC-80×4000 | 80 | 65 | 4000 | 245 | 3000 | 900 | 700 | 1000 | 3 | 2×30 |

| Model | Max. Thickness of Steel Plate for Rolling (mm) | Max. Thickness of Steel Plate for Pre-bending (mm) | Max. Width of Steel Plate for Rolling (mm) | Yield Limit of Steel Plate (Mpa) | Min. Rolling Diameter with Full Load (mm) | Diameter of Upper Roller (mm) | Diameter of Lower Roller (mm) | Diameter of Supporting Roller (mm) | Center Distance of Lower Rollers (mm) | Rolling Speed (m/min) | Power of Main Motor (kw) |

| W11XNC-100×3000 | 100 | 85 | 3000 | 245 | 2800 | 900 | 680 | -- | 1000 | 3 | 4×22 |

| W11XNC-100×4000 | 100 | 85 | 4000 | 245 | 3500 | 980 | 500 | 500 | 1050 | 3 | 4×30 |

| W11XNC-120×3000 | 120 | 100 | 3000 | 245 | 3000 | 950 | 720 | -- | 1050 | 3 | 4×30 |

| W11XNC-120×4000 | 120 | 100 | 4000 | 245 | 4000 | 1020 | 550 | 550 | 1050 | 3 | 4×30 |

| W11XNC-140×3500 | 140 | 120 | 3500 | 245 | 3500 | 1020 | 520 | 550 | 1100 | 3 | 4×30 |

| W11XNC-140×4000 | 140 | 120 | 4000 | 245 | 4000 | 1100 | 600 | 650 | 1200 | 3 | 4×45 |

| W11XNC-160×4000 | 160 | 140 | 4000 | 245 | 4000 | 1280 | 650 | 650 | 1350 | 3 | 4×55 |

| W11XNC-180×4000 | 180 | 160 | 4000 | 245 | 4000 | 1350 | 1100 | -- | 1560 | 2.5 | 4×55 |

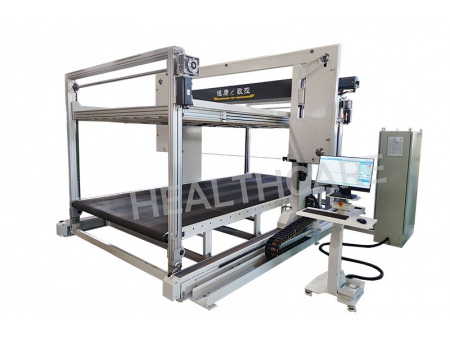

As a China horizontal 3-roller rolling machine manufacturer, at Zhouxiang Group we also offer hydraulic symmetrical 3-roller rolling machine, H-beam steel production line, laser steel pipe/board cutting machine, and more.