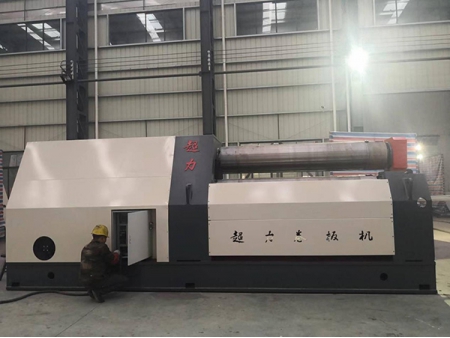

4 Roll Plate Bending Machine

The 4 roll hydraulic plate bending machine is suitable for plates of a 2-100mm thickness and a 1000-6000mm width.

This roll plate bending machine is widely used in manufacturing barrels for pressure vessels, various machinery, hydro power and construction, among other industries. It also comes with a roundness calibration function. The top roll is driven by a hydraulic motor. The friction between the metal plate and the top roll drives the bottom roll and lateral roll rotation, and supplies the torque for bending plates. The bottom roll, lateral roll and drop end are all driven by a hydraulic oil cylinder. The bottom roll moves up and down, and the side roll moves in an arc. The bottom roll rises to clamp the plate, and the side roll tilts up to pre-bend the end of the plate.

Features:

1. The machine is easy to operate, and has multiple bending methods.

2. CNC control, digital display of the movement of each roll, a high bending accuracy and excellent roundness all add to the overall efficiency of the plate bending machine.

3. A full hydraulic drive makes the machine energy efficient: the driving power is 60% that of a traditional machine.

4. One stage bending, the productivity reaches 50-80% higher than a 3 roll bending machine.

5. Material alignment is convenient and accurate, allowing users to easily avoid misalignments.

6. With a cone bending device, it is easy to bend the cones.

7. The plate bending machine comes with a permanent lubrication technology. There is no need to lubricate throughout the bearing’s service life.

8. The top and bottom rolls clamp the plate during the bending process with no slipping.

9. The minimum bending diameter of the cylinder is 1.1 times that of the diameter of the top roll. The surplus flat edge is smaller than it is on any other type of pate bending machine.

10. The carrying device, feeding device and support device are all easily installed.

11. This roll plate bending machine is CE certified.

Optional Equipment:

1. Lateral and overhead supports for metal sheets of large diameters

2. Material feeding table

3. Oil cooling system

4. Polished roll

| Model | Max. Bending Thickness (mm) | Max. pre-bending Thickness (mm) | Working Length of Rolls (mm) | Yield Limit (Mpa) | Top roll Diameter (mm) | Main Motor Power (KW) |

| 4 | 3.5 | 2050 | 245 | 160 | 3 | |

| 6 | 5 | 2050 | 245 | 190 | 4 | |

| 8 | 7 | 2050 | 245 | 210 | 5.5 | |

| 10 | 8 | 2050 | 245 | 230 | 7.5 | |

| 12 | 10 | 2050 | 245 | 270 | 11 | |

| 16 | 12 | 2050 | 245 | 300 | 11 | |

| 20 | 16 | 2050 | 245 | 330 | 11 | |

| 25 | 20 | 2050 | 245 | 360 | 15 | |

| 30 | 25 | 2050 | 245 | 390 | 18.5 | |

| 35 | 28 | 2050 | 245 | 430 | 22 | |

| 40 | 32 | 2050 | 245 | 460 | 30 | |

| 45 | 36 | 2050 | 245 | 510 | 37 | |

| 50 | 40 | 2050 | 245 | 550 | 45 | |

| 4 | 3.5 | 2550 | 245 | 190 | 4 | |

| 6 | 5 | 2550 | 245 | 210 | 5.5 | |

| 8 | 7 | 2550 | 245 | 230 | 7.5 | |

| 10 | 8 | 2550 | 245 | 270 | 11 | |

| 12 | 10 | 2550 | 245 | 300 | 11 | |

| 16 | 12 | 2550 | 245 | 330 | 11 | |

| 20 | 18 | 2550 | 245 | 360 | 15 | |

| 25 | 20 | 2550 | 245 | 390 | 18.5 | |

| 30 | 25 | 2550 | 245 | 430 | 22 | |

| 35 | 28 | 2550 | 245 | 460 | 30 | |

| 40 | 32 | 2550 | 245 | 510 | 37 | |

| 45 | 36 | 2550 | 245 | 550 | 45 | |

| 4 | 3.5 | 3100 | 245 | 210 | 5.5 | |

| 6 | 5 | 3100 | 245 | 230 | 7.5 | |

| 8 | 7 | 3100 | 245 | 270 | 11 | |

| 10 | 8 | 3100 | 245 | 300 | 11 | |

| 12 | 10 | 3100 | 245 | 330 | 11 | |

| 16 | 12 | 3100 | 245 | 360 | 15 | |

| 20 | 16 | 3100 | 245 | 390 | 18.5 | |

| 25 | 20 | 3100 | 245 | 430 | 22 | |

| 30 | 25 | 3100 | 245 | 460 | 30 | |

| 35 | 28 | 3100 | 245 | 510 | 37 | |

| 40 | 32 | 3100 | 245 | 550 | 45 | |

| 50 | 40 | 3100 | 245 | 610 | 55 | |

| 60 | 48 | 3100 | 245 | 670 | 75 |

- Hydraulic system

- Optional polished roll

- Hydrocylinder

- Hydraulic drop end

Maintenance and Inspection

1. Daily inspection items

Inspection of the hydraulic power box’s appearance

Inspection of oil in the power control box

Leakage of the pipeline system

Leakage of the pumps, valves, cylinders and the others

2. Periodic inspection items: 500-600 hours (60-75 days)

Detailed examination of the daily inspection items

Inspection of the hydraulic system actions, the functions at the maximum working pressure

3. Replace the working medium

Along with inspection of the oil in the power control box and adding oil according to the above daily inspection requirements, users should also change the oil completely each year. Before changing the oil, remove the cover of the hydraulic power box and clean the oil pump filter and the inside of the power control box.