Extrusion Press (for Φ170mm Rod)

Extrusion Machinery for Copper Rod, Rod Extrusion Equipment, Brass Rod Extruder

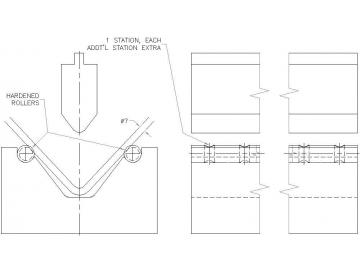

Indirect extrusion press is different from direct extrusion press. The hollow ram is outfitted with a die and drives the stationary metal billet at a reverse direction. Finally, the extruded copper parts will come out from the hollow ram.

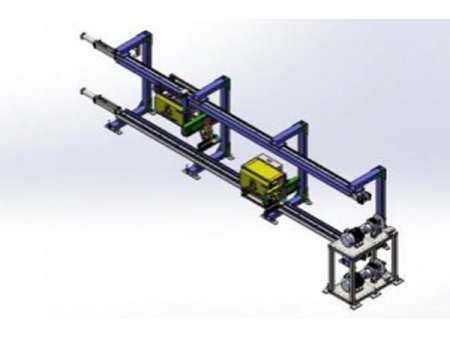

Main characteristics of Extrusion Machinery for Copper Rod

1. No friction or heat.

2. 25%-30% extrusion force less.

3. This rod extrusion equipment is applicable for profiles with a smaller cross sectional area. Plus, it can work under low temperature and at a high speed.

4. The brass rod extruder ensures uniform copper flow, small extrusion hole and low residual pressure, all allowing for reliable and excellent mechanical performance of extruded products.

| Model (Cu) | Rated pressure (MPa) | Size of standard copper billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW | |

| Metric ton | Short ton | |||||||

| 25 | Φ305×1220 | Φ170 | 170 | Φ315×150 | 1900 | 2500 | ||

Applications

Electronic components, solar energy tubes, transformer parts, etc.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.